Where can i print on transfer paper – Embark on a comprehensive journey into the world of transfer paper printing, where you’ll discover the secrets to transforming your designs onto a myriad of surfaces. From fabrics to ceramics and beyond, this guide will empower you with the knowledge and techniques to unleash your creativity and bring your visions to life.

Delve into the intricacies of transfer paper types, their compatibility with different materials, and the step-by-step process of printing, transferring, and curing. Whether you’re a seasoned pro or just starting your transfer paper adventure, this guide will equip you with the essential information and inspiration to elevate your projects to new heights.

Transfer Paper Basics

Transfer paper is a specialized paper coated with a heat-activated adhesive that allows you to transfer images, designs, or text onto various surfaces.

There are different types of transfer paper available, each designed for specific printing methods and compatible with different materials. The most common types include:

Laser Transfer Paper

- Designed for use with laser printers.

- Produces sharp, high-resolution transfers.

- Suitable for transferring onto light-colored fabrics, ceramics, and wood.

Inkjet Transfer Paper

- Designed for use with inkjet printers.

- Produces vibrant, full-color transfers.

- Suitable for transferring onto dark-colored fabrics, ceramics, and wood.

Sublimation Transfer Paper

- Designed for use with sublimation printers.

- Produces permanent, fade-resistant transfers.

- Suitable for transferring onto fabrics, ceramics, and other heat-resistant materials.

The process of using transfer paper involves:

- Printing the desired image or design onto the transfer paper using a compatible printer.

- Positioning the transfer paper on the surface to be decorated.

- Applying heat and pressure using a heat press or iron to transfer the image onto the surface.

- Curing the transfer to ensure a permanent bond between the image and the surface.

Printing on Transfer Paper

Printing on transfer paper involves transferring an image or design onto a substrate, such as fabric, wood, or ceramic, using a specialized printer and compatible inks.

Preparing the Image for Printing

Before printing, the image must be prepared in a compatible format and size for the transfer paper. High-resolution images with a resolution of at least 300 dpi are recommended for sharp and clear prints. The image should be mirrored or reversed if the transfer paper requires it.

Selecting the Appropriate Printer Settings

The printer settings must be adjusted to ensure optimal print quality. The printer driver should be set to the highest resolution available, and the paper type should be set to “transfer paper” or a similar setting. Additionally, the printer settings may include options for adjusting color balance, contrast, and brightness.

Applying the Transfer Paper to the Substrate

The transfer paper is applied to the substrate using heat and pressure. The specific application method depends on the type of transfer paper and substrate. For example, heat presses are commonly used for applying transfer paper to fabrics, while sublimation printers use heat and pressure to transfer the image directly onto the substrate.

Importance of Using Compatible Printers and Inks

Using compatible printers and inks is crucial for successful transfer printing. Incompatible printers or inks may not produce the desired results or may damage the transfer paper or substrate.

Incompatible printers may not have the necessary features or settings to support transfer printing. For example, some printers may not be able to handle the thickness of transfer paper or may not have the appropriate print resolution.

Incompatible inks may not adhere properly to the transfer paper or may not transfer to the substrate correctly. This can result in poor print quality or the image peeling off the substrate.

Tips for Achieving High-Quality Prints

- Use high-quality transfer paper designed for the specific substrate.

- Optimize printer settings for the best resolution and color accuracy.

- Ensure proper application of the transfer paper to the substrate, following the manufacturer’s instructions.

Troubleshooting Common Problems

If problems occur during transfer printing, identifying the cause and finding a solution is essential.

Some common problems include:

- Blurry or faded prints:This can be caused by low print resolution, incorrect printer settings, or improper application of the transfer paper.

- Peeling or cracking of the image:This can be caused by incompatible inks, insufficient heat or pressure during application, or improper preparation of the substrate.

- Color inaccuracies:This can be caused by incorrect color calibration of the printer or using incompatible inks.

By identifying the cause of the problem and applying appropriate solutions, such as adjusting printer settings, using compatible inks, or reapplying the transfer paper correctly, high-quality transfer prints can be achieved.

Selecting a Printing Service

Choosing the right printing service is crucial for ensuring high-quality transfer paper prints. Several factors need to be considered, including the printing method, cost, turnaround time, and quality.

Printing Methods

- Laser Printing:Offers precise and detailed prints, suitable for small to medium-sized batches. However, it may not be cost-effective for large orders.

- Inkjet Printing:Produces vibrant and high-resolution prints, ideal for photographic images. It is generally more expensive than laser printing but offers better color accuracy.

- Thermal Printing:Uses heat to transfer ink onto paper, resulting in durable and water-resistant prints. It is often used for industrial applications and is not suitable for high-quality image reproduction.

Cost Comparison

| Printing Method | Cost per Page | Turnaround Time | Quality |

|---|---|---|---|

| Laser Printing | $0.05-$0.15 | 1-2 business days | Good |

| Inkjet Printing | $0.10-$0.25 | 1-3 business days | Excellent |

| Thermal Printing | $0.02-$0.08 | Immediate | Fair |

Note: Costs and turnaround times may vary depending on the specific printing service and order size.

Provide detailed s for transferring designs using different techniques, including

Transferring designs onto various surfaces is a common practice in art, crafting, and home décor. There are several techniques available, each with its unique advantages and applications. This section will delve into the details of transferring designs using carbon paper, tracing paper, iron-on transfer paper, decoupage, and stenciling.

Carbon Paper

Carbon paper is a thin sheet coated with a layer of carbon or graphite. It is placed between the design and the surface to be transferred, and pressure is applied to transfer the design. Carbon paper is ideal for transferring simple designs or text onto hard surfaces like wood or metal.

Tracing Paper

Tracing paper is a translucent paper that allows the design to be seen through. It is placed over the design, and the Artikels are traced onto the surface below. Tracing paper is suitable for transferring detailed designs onto smooth surfaces like paper or fabric.

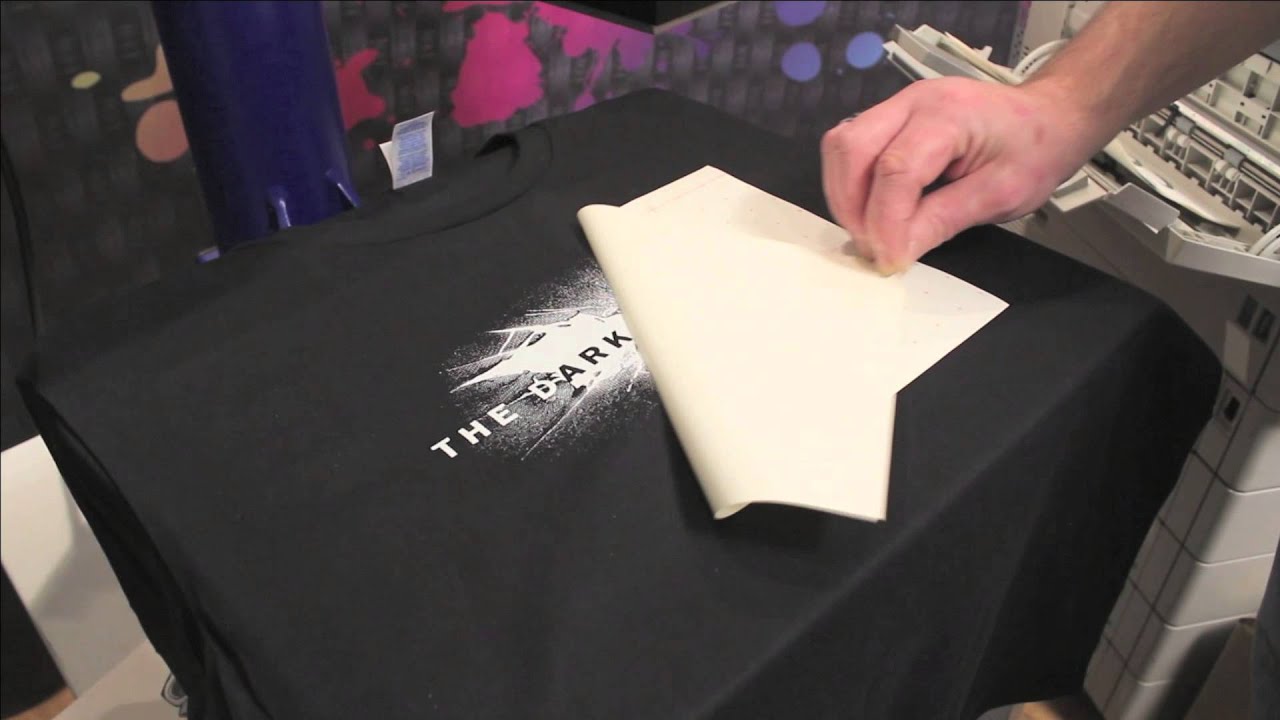

Iron-on Transfer Paper

Iron-on transfer paper is a specialized paper coated with a heat-activated adhesive. The design is printed onto the paper, and the paper is then placed on the surface to be transferred. Heat is applied with an iron or heat press, which causes the adhesive to bond the design to the surface.

Iron-on transfer paper is commonly used for transferring designs onto fabrics and other heat-resistant materials.

Decoupage

Decoupage is a technique that involves cutting out designs from paper or fabric and gluing them onto a surface. The glued design is then sealed with a protective coating, such as varnish or Mod Podge. Decoupage is a versatile technique that can be used on a wide range of surfaces, including wood, glass, and ceramics.

Stenciling

Stenciling involves creating a reusable template with the desired design cut out. The stencil is placed over the surface, and paint or ink is applied through the cutouts to transfer the design. Stenciling is suitable for creating repeated patterns or designs on large surfaces like walls or floors.

Troubleshooting Printing Issues

Printing issues can arise during the transfer paper printing process, affecting print quality, color accuracy, or transferability. Understanding common problems and their solutions can help resolve these issues effectively.

To troubleshoot printing errors, a systematic approach is recommended. Start by checking the printer settings, ensuring they align with the transfer paper specifications. Inspect the transfer paper for any damage or defects. If the issue persists, consider the following steps:

Print Quality Issues

- Blurry or pixelated prints:Check the print resolution settings in the printer software. Increase the resolution to enhance print quality.

- Faded or dull colors:Ensure the printer ink cartridges are full and not expired. Calibrate the printer to adjust color settings.

- Streaks or lines on the print:Clean the printer nozzles using the manufacturer’s recommended cleaning procedure.

Color Accuracy Issues

- Colors not matching the original design:Calibrate the printer using a color calibration tool to ensure accurate color reproduction.

- Colors appearing too dark or light:Adjust the brightness and contrast settings in the printer software to achieve the desired color balance.

Transferability Issues

- Design not transferring completely:Increase the print density or use a higher-quality transfer paper with improved adhesion.

- Design peeling or cracking after transfer:Allow the print to dry thoroughly before transferring. Use a heat press or iron at the recommended temperature and pressure.

Design Considerations: Where Can I Print On Transfer Paper

Design optimization is crucial for successful transfer printing. Factors such as resolution, color profiles, and file formats significantly impact the quality of the transferred design.

High-resolution designs ensure sharp and detailed prints. The recommended resolution varies depending on the printing method. Color profiles determine the accuracy of color reproduction, and selecting the appropriate profile for the specific transfer paper and printer is essential.

File Formats

The choice of file format affects the compatibility with different printing software and the quality of the print. Common file formats used for transfer printing include:

- PNG: Supports transparency and high resolution.

- JPEG: Suitable for images with a lot of color variations.

- PDF: Preserves the original design and is suitable for complex designs.

“Optimizing designs for transfer printing is paramount to achieving professional-looking results. Careful attention to resolution, color profiles, and file formats ensures the seamless transfer of intricate details and vibrant colors.”

Industry Expert

Checklist for Design Creation

- Determine the printing method and choose the appropriate resolution.

- Select the correct color profile for the transfer paper and printer.

- Choose a suitable file format that supports high resolution and transparency.

- Create designs with clear and sharp lines, avoiding excessive detail.

- Test the design on a small scale before printing the final product.

Applications of Transfer Paper

Transfer paper offers a versatile solution for transferring designs onto various surfaces, opening up a wide range of applications in different industries and creative endeavors.

From personalized t-shirts and fabric crafts to home décor and industrial uses, transfer paper enables users to create custom designs and enhance existing items with intricate patterns, vibrant colors, and photographic-quality images.

T-Shirt Printing

One of the most popular applications of transfer paper is in t-shirt printing. Transfer paper allows for the creation of custom t-shirts with unique designs, slogans, or images. The process involves printing the design onto transfer paper using a specialized printer, then transferring the design onto the t-shirt using a heat press or iron.

Transfer paper is particularly suitable for small-scale t-shirt printing, as it offers a cost-effective and easy-to-use solution compared to screen printing or direct-to-garment printing methods.

Fabric Crafts

Transfer paper is also widely used in fabric crafts, allowing crafters to add intricate designs and patterns to various fabrics. From tote bags and pillowcases to quilts and curtains, transfer paper enables the creation of personalized and unique fabric items.

The process of transferring designs onto fabric using transfer paper is similar to that of t-shirt printing, involving the use of a specialized printer and a heat press or iron. Transfer paper is particularly suitable for small-scale fabric crafts, as it allows for precise and detailed designs.

When printing on transfer paper, selecting the appropriate printer is crucial. Some printers may support cardstock, which is a thicker paper often used for business cards and invitations. If you’re considering using cardstock in your printer, check the manufacturer’s specifications to ensure compatibility.

For more information on using cardstock in printers, refer to can you use cardstock in a printer. Once you’ve determined the compatibility of your printer, you can proceed with printing on transfer paper to create custom designs or transfer images to other surfaces.

Home Décor

Transfer paper has also found applications in home décor, allowing users to add personalized touches to various household items. From coasters and mugs to lampshades and wall art, transfer paper enables the creation of unique and stylish home décor items.

The use of transfer paper in home décor offers a cost-effective and convenient way to update or customize existing items, or to create one-of-a-kind pieces that reflect personal style and preferences.

Industrial Uses

Beyond creative applications, transfer paper also has various industrial uses, such as in the production of printed circuit boards, medical devices, and automotive parts. Transfer paper is used to transfer designs and patterns onto these surfaces with precision and durability.

In industrial applications, transfer paper is often used in conjunction with specialized printing equipment and processes to ensure high-quality and consistent results.

To print on transfer paper, you can use a variety of methods. One popular method is to print from Pinterest. By following the steps outlined in how to print from pinterest , you can easily print your favorite images and designs onto transfer paper.

Once printed, you can then transfer your designs to a variety of surfaces, such as fabric, wood, or metal.

Safety and Precautions

Transfer paper can be a safe and convenient way to transfer designs onto various surfaces, but it’s essential to handle and use it safely to avoid potential hazards.

The primary hazard associated with transfer paper is the potential for chemical exposure. Transfer paper contains chemicals that can be harmful if inhaled, ingested, or absorbed through the skin. It’s crucial to follow safety guidelines to minimize exposure to these chemicals.

Potential Hazards

- Inhalation:Inhaling fumes or dust from transfer paper can cause respiratory irritation, coughing, and shortness of breath.

- Ingestion:Swallowing transfer paper or its chemicals can lead to nausea, vomiting, and other digestive issues.

- Skin contact:Prolonged or repeated skin contact with transfer paper can cause irritation, redness, and allergic reactions.

- Eye contact:Contact with transfer paper or its chemicals can cause eye irritation, redness, and pain.

Safety Guidelines

- Use in a well-ventilated area:Ensure adequate ventilation when using transfer paper to minimize inhalation exposure.

- Wear gloves and a mask:Wear nitrile gloves and a NIOSH-approved respirator to protect your hands and respiratory system from chemical exposure.

- Avoid prolonged skin contact:Wear long sleeves, pants, and closed-toe shoes to minimize skin contact with transfer paper.

- Store transfer paper properly:Store transfer paper in a cool, dry place away from children and pets.

- Dispose of transfer paper safely:Dispose of used transfer paper and its packaging according to local regulations.

Safety Warning:Always read and follow the manufacturer’s instructions for handling and using transfer paper. If you experience any adverse reactions, seek medical attention immediately.

By following these safety guidelines, you can minimize the risks associated with using transfer paper and ensure a safe and enjoyable experience.

Safety Guidelines Table

| Hazard | Safety Guideline |

|---|---|

| Inhalation | Use in a well-ventilated area |

| Ingestion | Avoid eating or drinking around transfer paper |

| Skin contact | Wear gloves and long sleeves |

| Eye contact | Wear safety glasses |

| Storage | Store in a cool, dry place |

| Disposal | Dispose of according to local regulations |

Sustainability Considerations

Transfer paper, like many other materials used in printing, has an environmental impact that should be considered. Understanding the sustainability aspects of transfer paper helps in making informed choices and adopting responsible practices to minimize the environmental footprint.

Transfer paper is typically made from cellulose fibers, which come from trees. The production of transfer paper involves harvesting trees, processing the wood pulp, and treating it with chemicals to create the desired properties. These processes can contribute to deforestation, water pollution, and air pollution.

Disposing of Transfer Paper Responsibly

Disposing of transfer paper responsibly is crucial to minimize its environmental impact. Transfer paper can be recycled along with other paper waste. However, it is important to note that transfer paper with ink or toner residue should not be recycled as it can contaminate the recycling process.

For transfer paper with ink or toner residue, it is best to dispose of it as general waste. In some cases, specialized waste disposal services may be available for hazardous materials, which may include transfer paper with ink or toner residue.

Reducing Waste and Promoting Sustainability

There are several ways to reduce waste and promote sustainability in transfer printing:

- Use digital printing techniques whenever possible, as they produce less waste compared to traditional printing methods.

- Optimize print settings to minimize ink or toner usage.

- Use high-quality transfer paper to reduce the need for reprints due to smudging or fading.

- Reuse transfer paper whenever possible, such as for draft prints or test prints.

- Consider using eco-friendly transfer paper made from recycled materials or sustainable sources.

By adopting these practices, you can reduce the environmental impact of transfer printing and contribute to a more sustainable future.

Alternative Methods to Transfer Paper

Transfer paper is a versatile tool for transferring designs onto various surfaces, but it is not the only option. Alternative methods offer unique advantages and disadvantages, making them suitable for specific applications. This guide explores alternative methods to transfer paper, comparing their costs, ease of use, and quality.

The following table provides a quick overview of the alternative methods discussed in this guide:

| Method | Cost | Ease of Use | Quality |

|---|---|---|---|

| Screen Printing | Moderate | Intermediate | High |

| Vinyl Cutting | Low | Beginner | Medium |

| Sublimation Printing | Moderate | Intermediate | High |

| Decal Paper | Low | Beginner | Medium |

Screen Printing

Screen printing is a popular method for transferring designs onto textiles, ceramics, and other surfaces. It involves using a mesh screen to apply ink or paint through a stencil, creating a durable and vibrant image.

Advantages:

- Produces high-quality, long-lasting prints

- Suitable for large-scale production

- Versatile, can be used on various materials

Disadvantages:

- Requires specialized equipment and materials

- Can be time-consuming and labor-intensive

- Not suitable for small or intricate designs

Vinyl Cutting

Vinyl cutting uses a machine to cut designs from self-adhesive vinyl material. The cut designs can then be applied to surfaces such as glass, metal, or plastic.

Advantages:

- Low cost and easy to use

- Suitable for small or intricate designs

- Durable and weather-resistant

Disadvantages:

- Limited color options compared to other methods

- Can be difficult to remove without leaving residue

- Not suitable for large-scale production

Advanced Techniques

Transfer printing offers a wide range of advanced techniques that allow artists to create intricate and innovative designs. These techniques include layering, blending, and distress effects, which can add depth, texture, and character to transferred images.

Layering

Layering involves printing multiple layers of transfer paper onto a single surface. This technique allows artists to create complex designs with varying colors, patterns, and textures. To achieve layering, print the first layer of transfer paper onto the surface, let it dry completely, and then apply subsequent layers.

Each layer can be aligned precisely or offset to create different effects.

Blending

Blending involves using multiple colors of transfer paper to create smooth transitions and gradients. To achieve blending, print the first color onto the surface, let it dry partially, and then apply the second color while the first layer is still slightly damp.

The two colors will blend together, creating a seamless transition.

Distress Effects

Distress effects involve intentionally damaging or altering the transfer paper to create a vintage or weathered appearance. To achieve distress effects, crumple, tear, or sand the transfer paper before or after printing. The resulting imperfections will add character and depth to the transferred image.

Table of Advanced Techniques

| Technique | Advantages | Disadvantages ||—|—|—|| Layering | Creates complex designs with multiple colors and textures | Can be time-consuming || Blending | Smooth transitions and gradients | Requires precise timing and alignment || Distress Effects | Vintage or weathered appearance | Can damage the transfer paper |

Code Snippet for Layering Transfer Prints

“`function layerTransferPrints(numLayers) for (let i = 0; i < numLayers; i++) printTransferPaper(layer[i]); waitForTransferPaperToDry();```

Workflow for Creating Distressed Effects

- Print the transfer paper onto the surface.

- Crumple or tear the transfer paper.

- Smooth out the transfer paper and press it firmly onto the surface.

- Remove the transfer paper and let the image dry completely.

Industry Trends and Innovations

Transfer printing is constantly evolving, with new technologies and innovations emerging all the time. These advancements are shaping the industry in a number of ways, from improving the quality and efficiency of printing to expanding the range of applications for transfer paper.

One of the most significant trends in transfer printing is the development of new digital printing technologies. These technologies allow for more precise and accurate printing, as well as the ability to print on a wider range of materials. As a result, digital printing is becoming increasingly popular for a variety of applications, including garment decoration, signage, and product packaging.

Emerging Technologies

In addition to digital printing, a number of other emerging technologies are also having a major impact on the transfer printing industry. These technologies include:

- 3D printing:3D printing can be used to create custom-shaped transfer sheets, which can then be used to print designs on a variety of surfaces.

- Laser engraving:Laser engraving can be used to create intricate designs on transfer paper, which can then be used to print high-quality images on a variety of materials.

- Water-based inks:Water-based inks are becoming increasingly popular for transfer printing, as they are more environmentally friendly than traditional solvent-based inks.

Future of Transfer Printing

The future of transfer printing is bright. As new technologies continue to emerge, the industry is expected to continue to grow and evolve. In the coming years, we can expect to see even more innovative and versatile transfer printing solutions that will open up new possibilities for businesses and consumers alike.

Case Studies

Transfer paper has proven to be a valuable tool for businesses across various industries. The following case studies illustrate the success stories of companies that have leveraged transfer printing to grow and achieve their business goals.

Successful Implementation of Transfer Paper in the Textile Industry

A leading textile manufacturer faced challenges in meeting the growing demand for customized designs. By incorporating transfer paper into their production process, they were able to streamline their workflow and produce high-quality prints with intricate patterns and vibrant colors. This resulted in increased customer satisfaction and a significant boost in sales.

Transfer Printing for Personalized Gifts and Accessories

A small business specializing in personalized gifts and accessories used transfer paper to create unique and memorable products. By printing designs directly onto mugs, t-shirts, and other items, they were able to offer a wide range of options to their customers.

This resulted in a surge in demand and a substantial increase in revenue.

Transfer Paper in Educational Settings, Where can i print on transfer paper

An educational institution utilized transfer paper to enhance the learning experience for students. By printing educational materials, such as diagrams and charts, onto transfer paper and then transferring them to fabric or other surfaces, students could engage with the material in a more interactive and tactile way.

This led to improved comprehension and retention of knowledge.

Resources and Inspiration

Expanding your knowledge and seeking inspiration in transfer printing can be incredibly enriching. To assist you in this pursuit, we have compiled a comprehensive list of resources and curated a gallery of inspiring projects to ignite your creativity.

Our curated list of resources includes online communities, forums, and tutorials, providing a wealth of knowledge and support from fellow enthusiasts and experts in the field.

Online Communities and Forums

- Transfer Printing Hub:A dedicated online forum where users can connect, share knowledge, and discuss all aspects of transfer printing.

- Transfer Printing Association:An organization that provides resources, training, and networking opportunities for professionals in the transfer printing industry.

- Reddit Transfer Printing:A subreddit where hobbyists and professionals alike share tips, tricks, and project ideas.

Tutorials and Learning Resources

- Transfer Printing 101:A comprehensive guide covering the basics of transfer printing, from choosing the right materials to troubleshooting common issues.

- YouTube Tutorials:Numerous video tutorials are available online, demonstrating various transfer printing techniques and projects.

- Online Courses:Platforms like Udemy and Coursera offer online courses on transfer printing, providing structured learning experiences.

Inspiration Gallery

To inspire your creativity, we have compiled a gallery showcasing a diverse range of transfer printing projects. From intricate artwork to practical applications, these projects demonstrate the versatility and endless possibilities of transfer printing.

By accessing these resources and immersing yourself in the inspiring world of transfer printing, you can unlock new possibilities, enhance your skills, and create truly remarkable projects.

Commonly Asked Questions

Can I print on any type of fabric using transfer paper?

Not all fabrics are compatible with transfer paper. Synthetic fabrics like polyester and nylon work best, while natural fibers like cotton and linen may require special treatment or specific types of transfer paper.

What is the best way to prevent my transfer from fading or peeling?

Proper curing and sealing are crucial for ensuring the longevity of your transfer. Follow the recommended curing instructions for your specific transfer paper and apply a protective sealant to prevent fading and peeling.

Can I layer multiple transfer prints on top of each other?

Yes, layering transfer prints is possible, but it requires careful alignment and precise temperature control. Experiment with different techniques to achieve the desired effect.