What is the fuser on a printer – In the intricate world of printing, the fuser unit plays a pivotal role, bonding toner to paper to produce crisp, long-lasting documents. Understanding what is a fuser on a printer unveils the secrets behind this essential component, ensuring optimal performance and troubleshooting efficiency.

The fuser, located within the printer, comprises key components such as the heating element, pressure roller, and thermistor, each contributing to the fusing process. As the toner is transferred to the paper, the heating element raises its temperature, softening it.

The pressure roller then applies pressure, permanently fusing the toner to the paper, resulting in a durable print.

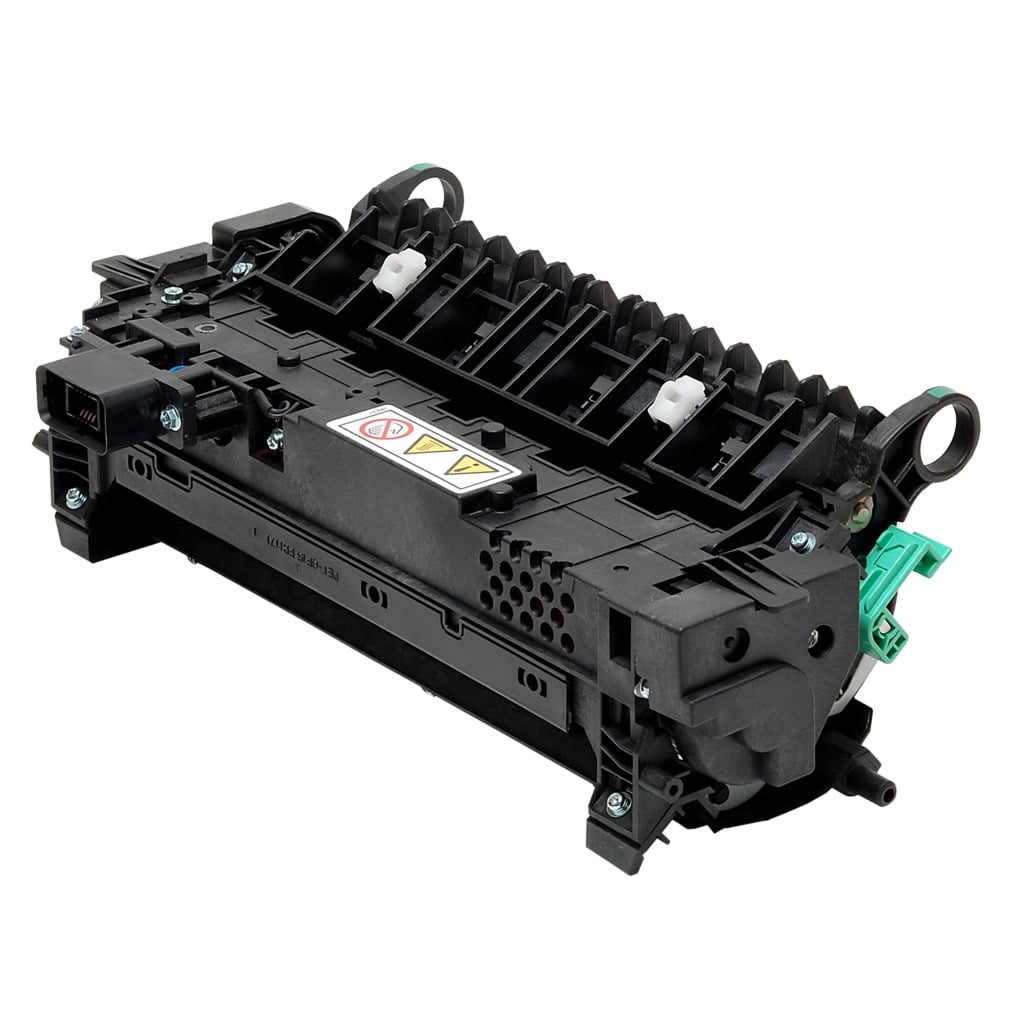

Overview of a Printer Fuser

A fuser, also known as a fusing unit, is a critical component of a laser printer or copier. Its primary purpose is to permanently bond toner particles to paper, creating a durable and smudge-free printed image.

The fuser is typically located at the end of the printer’s paper path, after the toner has been transferred to the paper. It consists of two heated rollers, a pressure roller, and a cooling roller.

Location and Appearance

The fuser is usually positioned near the printer’s output tray, where the printed pages emerge. It is often enclosed within a metal housing for safety and to prevent accidental contact with the heated rollers.

The fuser rollers are typically made of a heat-resistant material, such as Teflon or ceramic. The pressure roller applies pressure to the paper, while the heated rollers melt the toner particles and fuse them to the paper’s surface.

The cooling roller helps to cool the paper and prevent it from curling or wrinkling as it exits the printer.

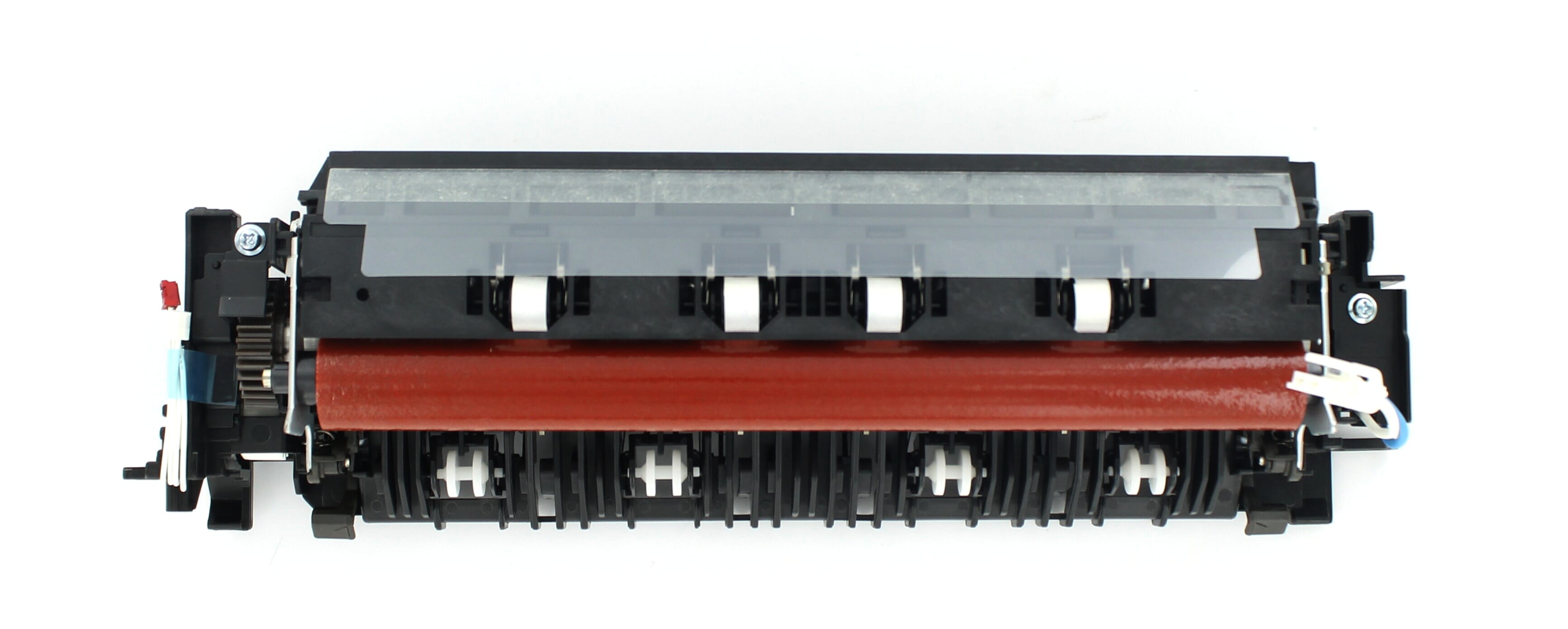

Components of a Fuser

The fuser unit in a printer is responsible for permanently bonding the toner particles to the paper, creating a durable and legible print. This process involves several key components working together to apply heat and pressure.

The main components of a fuser include:

- Heating Element:The heating element is responsible for generating the necessary heat to melt the toner particles. It is typically made of a ceramic or metal material and is heated to a high temperature.

- Pressure Roller:The pressure roller applies pressure to the paper as it passes through the fuser. This pressure helps to press the melted toner particles into the paper fibers, creating a strong bond.

- Thermistor:The thermistor is a temperature sensor that monitors the temperature of the heating element. It ensures that the heating element operates at the correct temperature to prevent damage to the paper or toner.

Fusing Process

The fusing process in a printer involves bonding toner particles to paper to create a permanent image. This process occurs within the fuser unit, which consists of heated rollers that apply pressure and heat to the toner and paper.

The fusing process typically involves the following steps:

- Preheating:The fuser rollers are heated to a specific temperature, typically between 150-200 degrees Celsius (300-390 degrees Fahrenheit).

- Toner Transfer:The toner particles, which have been transferred to the paper from the drum or imaging unit, are brought into contact with the heated fuser rollers.

- Melting:The heat from the rollers melts the toner particles, causing them to adhere to the paper.

- Fusing:The pressure applied by the rollers presses the melted toner into the paper fibers, creating a permanent bond.

- Cooling:The fused toner is then cooled as it exits the fuser unit, solidifying the bond between the toner and paper.

Temperature and Pressure

The temperature and pressure involved in the fusing process are crucial for ensuring proper toner adhesion. The temperature must be high enough to melt the toner particles without scorching the paper, while the pressure must be sufficient to press the melted toner into the paper fibers.

The optimal temperature and pressure settings vary depending on the type of toner and paper used.

Fuser Maintenance

Maintaining a fuser is essential to ensure optimal performance and longevity of the printer. Regular cleaning, lubrication, and troubleshooting can prevent common issues and extend the fuser’s lifespan.

The fuser on a printer is a critical component responsible for bonding toner to paper. After the toner is transferred to the paper, the fuser applies heat and pressure to melt the toner particles, creating a permanent bond. This process is essential for producing high-quality prints.

However, it is also possible to manipulate the fuser to alter a printed check. How to alter a printed check guides provide detailed instructions on how to adjust the fuser settings to modify the appearance of a printed check, making it easier to commit fraud.

Common issues that can occur with fusers include paper jams, wrinkles, and smudging. These issues can be caused by a variety of factors, such as dirt, dust, or toner buildup.

Cleaning and Lubrication

Regular cleaning and lubrication of the fuser can help prevent these issues. Cleaning should be done with a soft, lint-free cloth and a mild cleaning solution. Lubrication should be applied to the fuser’s moving parts, such as the rollers and gears, according to the manufacturer’s instructions.

Troubleshooting

If you are experiencing issues with your fuser, there are a few troubleshooting steps you can take:

- Check for paper jams or wrinkles.

- Clean the fuser with a soft, lint-free cloth and a mild cleaning solution.

- Lubricate the fuser’s moving parts according to the manufacturer’s instructions.

- If the issue persists, you may need to replace the fuser.

Replacing a Fuser, What is the fuser on a printer

Replacing a fuser is a relatively simple process. However, it is important to follow the manufacturer’s instructions carefully.

- Turn off the printer and unplug it from the power outlet.

- Open the printer’s cover and locate the fuser.

- Disconnect the fuser’s electrical connectors.

- Remove the old fuser and replace it with the new one.

- Reconnect the fuser’s electrical connectors.

- Close the printer’s cover and plug it back into the power outlet.

- Turn on the printer and test the fuser.

Common Issues, Causes, and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Paper jams | Dirt, dust, or toner buildup | Clean the fuser with a soft, lint-free cloth and a mild cleaning solution |

| Wrinkles | Fuser is not heating up properly | Check the fuser’s electrical connections and replace the fuser if necessary |

| Smudging | Fuser is too hot | Adjust the fuser’s temperature settings or replace the fuser if necessary |

Troubleshooting Flowchart

Troubleshooting Fuser Problems

Fuser problems can significantly impact the performance and efficiency of a printer. Identifying and resolving these issues promptly is crucial to maintain optimal printing quality and prevent further complications. Common fuser problems include paper jams, ghosting, and streaking, each with specific causes and solutions.

Paper Jams

Paper jams occur when paper becomes stuck in the fuser, preventing it from passing through smoothly. Causes of paper jams can include:

- Using incompatible or damaged paper

- Overloading the paper tray

- Misaligned paper guides

- Worn or damaged fuser rollers

To resolve paper jams, carefully remove the jammed paper, ensuring no fragments remain. Check the paper quality, adjust the paper guides, and replace any damaged components if necessary.

Ghosting

Ghosting refers to faint residual images or text appearing on printed pages. This problem is typically caused by:

- Worn or contaminated fuser rollers

- Insufficient heat or pressure during fusing

- Misalignment of the fuser rollers

To address ghosting, clean or replace the fuser rollers, adjust the fuser temperature and pressure settings, and ensure proper alignment of the rollers.

Streaking

Streaking is characterized by visible lines or smudges on printed pages. This issue can be attributed to:

- Dirty or damaged fuser rollers

- Worn or loose fuser bushings

- Improper fuser roller spacing

To resolve streaking, thoroughly clean or replace the fuser rollers, tighten loose bushings, and adjust the fuser roller spacing according to the manufacturer’s specifications.

Types of Fusers

Fusers are classified into various types based on their design and functionality. The primary types of fusers include inline fusers, offline fusers, and dual-mode fusers.

Inline Fusers

Inline fusers are integrated into the printer’s paper path and operate simultaneously with the printing process. They are compact and efficient, offering quick fusing times and reduced paper handling.

Offline Fusers

Offline fusers are separate units that are used for post-processing of printed materials. They are typically used for high-volume printing or for specialized applications that require specific fusing temperatures or capabilities.

Dual-Mode Fusers

Dual-mode fusers combine the features of inline and offline fusers. They can operate in both inline and offline modes, providing flexibility and versatility in printing operations.

| Type | Features | Benefits | Drawbacks |

|---|---|---|---|

| Inline Fusers | Integrated into printer, fast fusing | Compact, efficient | Limited fusing capabilities |

| Offline Fusers | Separate unit, specialized capabilities | High-volume printing, precise fusing | Separate unit, slower process |

| Dual-Mode Fusers | Combines inline and offline features | Flexibility, versatility | More complex, higher cost |

Safety Precautions

Fusers operate at high temperatures, posing potential hazards. Safety precautions are paramount to prevent accidents and ensure safe operation.

It’s crucial to adhere to the manufacturer’s instructions and follow established safety protocols when handling fusers.

Potential Hazards

- Heat and burns:Fusers generate intense heat, making contact with the fuser or surrounding components hazardous.

- Electrical shock:Fusers require a high electrical current, and improper handling can lead to electrical shocks.

- Fumes and odors:The fusing process can release fumes and odors that can irritate the respiratory system.

Safe Operation Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Ensure the printer is unplugged and cooled before handling the fuser.

- Handle the fuser with care, avoiding touching heated surfaces.

- Ventilate the area where the printer is located to minimize exposure to fumes.

- Do not attempt to repair or replace the fuser without proper training and authorization.

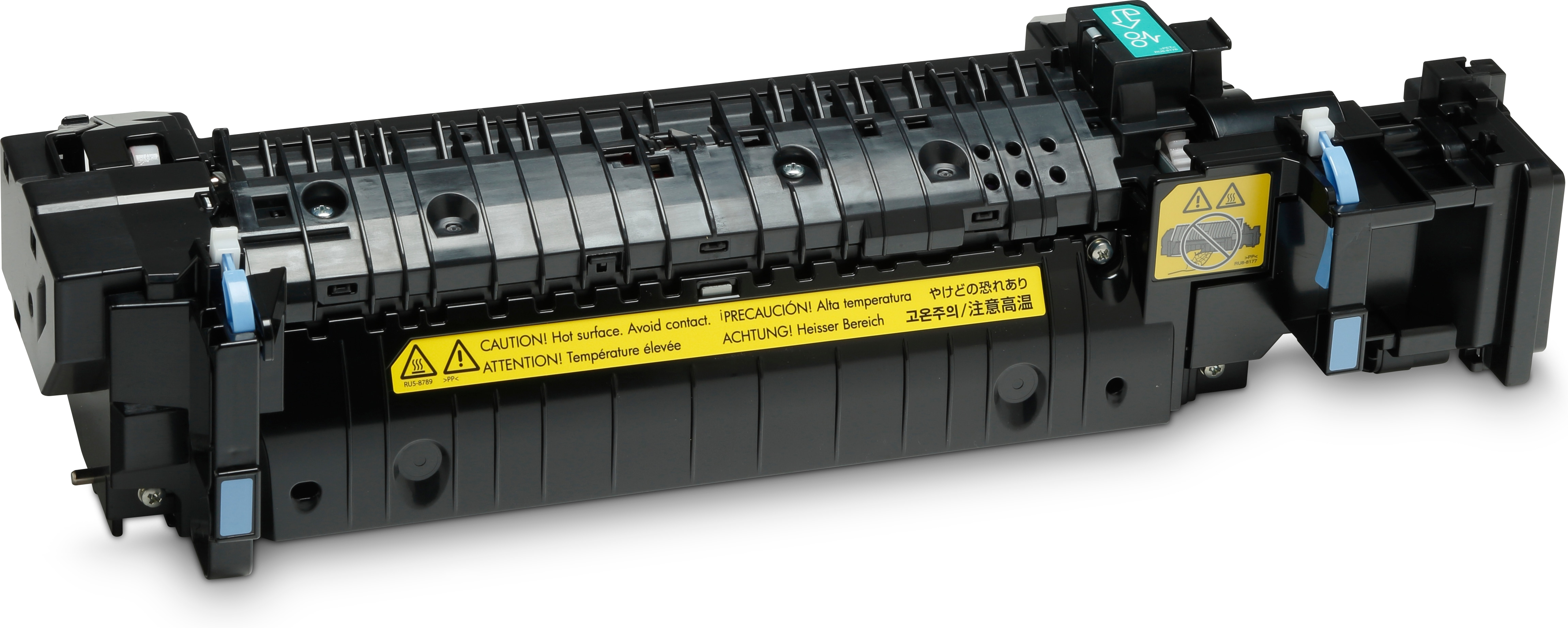

Fuser Replacement

Replacing a fuser in a printer is a straightforward process that can be completed in a few simple steps. Before attempting any repairs, unplug the printer from the power outlet for safety.

Required tools and materials:

- New fuser unit

- Phillips head screwdriver

- Gloves

- Safety glasses

Safety precautions:

- Wear gloves and safety glasses to protect yourself from hot surfaces and toner particles.

- Dispose of the old fuser properly according to local regulations.

Step-by-step guide:

- Open the printer’s cover and locate the fuser unit.

- Disconnect the power cable from the fuser unit.

- Unscrew the screws that hold the fuser unit in place.

- Carefully remove the old fuser unit.

- Insert the new fuser unit into the printer.

- Tighten the screws that hold the fuser unit in place.

- Reconnect the power cable to the fuser unit.

- Close the printer’s cover.

Troubleshooting tips:

- If the printer does not turn on after replacing the fuser, check that the power cable is securely connected.

- If the printer prints blank pages, check that the fuser unit is properly installed.

- If the printer prints smudged or faded pages, the fuser may need to be replaced again.

Note:Consult the printer’s user manual for specific instructions on how to replace the fuser.

Environmental Considerations: What Is The Fuser On A Printer

Fusers and toner cartridges can have a significant environmental impact, primarily due to their consumption of energy and resources, as well as the generation of waste. However, there are recycling and disposal options available to minimize their environmental impact.

The production of fusers and toner cartridges requires the extraction and processing of raw materials, which can lead to air and water pollution. Additionally, the use of fusers and toner cartridges consumes energy, which can contribute to greenhouse gas emissions.

Finally, the disposal of used fusers and toner cartridges can create waste and contribute to landfill pollution.

Recycling and Disposal Options

Recycling fusers and toner cartridges is an important way to reduce their environmental impact. Many manufacturers offer recycling programs for their products, and there are also a number of third-party companies that recycle fusers and toner cartridges.

When recycling fusers and toner cartridges, it is important to follow the manufacturer’s instructions. Some fusers and toner cartridges may contain hazardous materials, so it is important to dispose of them properly.

Environmental Impact of Different Types of Fusers

| Type of Fuser | Energy Consumption | Waste Generation | Greenhouse Gas Emissions |

|---|---|---|---|

| Laser Fusers | High | Low | Moderate |

| LED Fusers | Low | Low | Low |

| Inkjet Fusers | Very Low | High | Very Low |

Tips for Reducing the Environmental Impact of Fusers and Toner Cartridges

- Use fusers and toner cartridges that are energy-efficient.

- Recycle fusers and toner cartridges whenever possible.

- Dispose of used fusers and toner cartridges properly.

- Use printers that have a low environmental impact.

Importance of Recycling Fusers and Toner Cartridges

Recycling fusers and toner cartridges is important for several reasons. First, it helps to conserve natural resources. Second, it reduces the amount of waste that is sent to landfills. Third, it can help to reduce greenhouse gas emissions.

By recycling fusers and toner cartridges, you can help to protect the environment and reduce your environmental impact.

10. Advanced Fuser Technologies

Fuser technology has advanced significantly in recent years, with the emergence of low-temperature fusing and non-contact fusing. These technologies offer several benefits, including reduced energy consumption, improved print quality, and increased durability.

Low-Temperature Fusing

Low-temperature fusing uses a lower temperature to fuse the toner to the paper, typically around 100-120 degrees Celsius. This reduces energy consumption and can extend the life of the fuser. Additionally, low-temperature fusing can improve print quality by preventing the toner from scorching or bleeding.

Non-Contact Fusing

Non-contact fusing uses a laser or infrared beam to fuse the toner to the paper without direct contact. This eliminates the need for a heated roller, which can further reduce energy consumption and extend the life of the fuser. Non-contact fusing also produces high-quality prints with sharp edges and vibrant colors.

The fuser is a critical component in a printer, responsible for fusing toner particles onto paper to create a permanent image. If you encounter issues connecting your Canon printer to your phone, a comprehensive guide is available here. Returning to the fuser, it applies heat and pressure to the toner, ensuring a strong bond between the toner and paper.

Understanding the fuser’s function is essential for maintaining optimal printer performance.

Comparison of Technologies

The table below summarizes the key features, benefits, and limitations of low-temperature fusing and non-contact fusing:| Technology | Features | Benefits | Limitations ||—|—|—|—|| Low-Temperature Fusing | Lower fusing temperature | Reduced energy consumption, improved print quality, extended fuser life | May require specialized toner || Non-Contact Fusing | No heated roller | Reduced energy consumption, extended fuser life, high-quality prints | More expensive than traditional fusers |

Industry Applications

Low-temperature fusing and non-contact fusing are being used in a variety of applications, including:* Office printers:Low-temperature fusing is becoming increasingly common in office printers, as it offers a balance of energy efficiency and print quality.

Production printers

Non-contact fusing is often used in production printers, as it can produce high-quality prints at high speeds.

Industrial printers

Both low-temperature fusing and non-contact fusing are used in industrial printers, where durability and energy efficiency are important considerations.

Potential Future Developments

Future developments in fuser technologies may include:* Further reductions in fusing temperature:This could lead to even lower energy consumption and improved print quality.

New fusing methods

Researchers are exploring new ways to fuse toner to paper, such as using ultrasonic waves or microwaves.

Self-cleaning fusers

This could reduce maintenance costs and improve print quality.

Key Insights and Recommendations

Businesses considering adopting advanced fuser technologies should consider the following:* Energy consumption:Low-temperature fusing can significantly reduce energy consumption, which can lead to cost savings.

Print quality

Non-contact fusing can produce high-quality prints with sharp edges and vibrant colors.

Durability

Both low-temperature fusing and non-contact fusing can extend the life of the fuser.

Cost

Non-contact fusers are more expensive than traditional fusers, but they may offer a better return on investment over time.

Fuser in Different Printer Types

Fusers are essential components of printers, responsible for fusing toner or ink onto paper to create permanent prints. Different types of printers utilize distinct fuser mechanisms tailored to their specific printing technologies.

Laser Printers

Laser printers employ fusers that heat toner particles to a temperature where they adhere to the paper. These fusers typically consist of a heated roller and a pressure roller that applies pressure to the paper, ensuring the toner bonds securely.

Inkjet Printers

Inkjet printers use fusers that heat the ink droplets to evaporate the solvent and fix the ink pigments onto the paper. These fusers often employ infrared or ultraviolet light sources to generate heat, which is directed onto the printed page.

Other Printer Types

Other types of printers, such as dot-matrix printers and thermal printers, utilize different fuser mechanisms. Dot-matrix printers use heated pins to impact the paper, creating characters or images. Thermal printers employ heat-sensitive paper that darkens when exposed to heat, forming the desired print.

| Feature | Laser Printers | Inkjet Printers | Other Printer Types |

|---|---|---|---|

| Fusing Mechanism | Heated roller and pressure roller | Infrared or UV light | Heated pins or heat-sensitive paper |

| Temperature Range | 140-200°C (284-392°F) | 60-120°C (140-248°F) | Varies depending on technology |

| Print Quality | High | Medium to high | Low to medium |

| Speed | Fast | Slower | Slowest |

Troubleshooting Common Fuser Issues

Fusers can encounter various issues that affect print quality or printer functionality. Some common problems include:

- Wrinkled or curled paper

- Faded or smeared prints

- Paper jams

- Overheating or burning smell

To troubleshoot these issues, check the fuser for any visible damage, clean the fuser components, or replace the fuser if necessary. Consult the printer manufacturer’s instructions for specific troubleshooting steps.

Fuser Design Variations

Fuser designs vary in size, shape, cooling systems, and roller materials. These variations impact fuser performance and efficiency, including factors such as fusing temperature, speed, and energy consumption.

For instance, smaller fusers are more compact and consume less energy, but they may have a lower fusing temperature and speed. Larger fusers, on the other hand, can handle higher volumes and speeds but require more energy and space.

Shape

Fusers come in various shapes, such as cylindrical, flat, and U-shaped. Cylindrical fusers are commonly used in laser printers and offer high fusing speeds and temperatures. Flat fusers are found in inkjet printers and provide even heat distribution. U-shaped fusers combine the advantages of both cylindrical and flat fusers, offering high speeds and even heat distribution.

Cooling Systems

Fusers employ different cooling systems to dissipate heat generated during the fusing process. Air-cooled fusers use fans to circulate air around the fuser, while liquid-cooled fusers use a coolant to absorb and dissipate heat. Liquid-cooled fusers provide more efficient cooling and can handle higher temperatures, making them suitable for high-volume printing.

Roller Materials

Fusers utilize various roller materials, such as silicone, rubber, and Teflon. Silicone rollers offer high heat resistance and durability, while rubber rollers provide better grip and pressure. Teflon rollers have a low coefficient of friction, reducing wear and tear. The choice of roller material depends on the specific printing requirements and desired performance.

Table: Key Design Variations and Impact on Fuser Performance

| Design Variation | Impact on Fuser Performance |

|---|---|

| Size | Compactness, energy consumption, fusing temperature, speed |

| Shape | Fusing speed, temperature, heat distribution |

| Cooling Systems | Cooling efficiency, temperature handling, volume capacity |

| Roller Materials | Heat resistance, durability, grip, pressure, friction |

In summary, fuser design variations significantly influence fuser performance and efficiency. Smaller fusers offer compactness and energy efficiency but may have lower fusing temperature and speed. Different shapes provide varying heat distribution and speed capabilities. Cooling systems affect temperature handling and volume capacity, while roller materials impact heat resistance, durability, and grip.

Fuser Specifications

Fuser specifications are critical in determining the performance and quality of a printer. These specifications include fusing temperature, pressure, and speed, each playing a vital role in the fusing process.

Fusing temperature refers to the temperature at which the fuser heats the toner particles to bond them to the paper. This temperature must be precisely controlled to ensure proper adhesion without damaging the paper or toner.

Pressure

Fuser pressure is the force applied by the fuser rollers to press the toner particles onto the paper. Adequate pressure is necessary to create a strong bond between the toner and paper, preventing smudging or flaking.

Speed

Fuser speed refers to the rate at which the fuser moves the paper through the fusing process. The speed must be synchronized with the printer’s printing speed to ensure that the toner is properly fused before the paper exits the printer.

| Specification | Significance |

|---|---|

| Fusing Temperature | Determines the strength and durability of the bond between toner and paper. |

| Pressure | Ensures proper adhesion of toner particles to the paper, preventing smudging or flaking. |

| Speed | Synchronizes with the printer’s printing speed to ensure proper fusing before paper exits the printer. |

Fuser Compatibility

Using the correct fuser for a specific printer model is crucial for optimal performance and longevity of the printer. Each printer model is designed to work with a specific fuser that meets its unique specifications, such as size, power consumption, and temperature requirements.Consequences of using an incompatible fuser can be severe, including:

Poor print quality

An incompatible fuser may not be able to fuse the toner particles properly, resulting in faded or smudged prints.

Paper jams

An incompatible fuser may not be able to handle the specific paper type or thickness, leading to paper jams and damage to the printer.

Overheating

An incompatible fuser may draw too much power or generate excessive heat, potentially causing the printer to overheat and shut down.

Damage to the printer

Using an incompatible fuser can put excessive strain on the printer’s components, potentially damaging the printer and voiding the warranty.

FAQ Compilation

What is the purpose of a fuser in a printer?

The fuser bonds toner to paper, creating permanent, high-quality prints.

Where is the fuser located in a printer?

The fuser is typically located near the end of the paper path, before the paper exits the printer.

What are common fuser problems?

Common fuser problems include paper jams, ghosting, and streaking, often caused by incorrect temperature settings or worn components.