How to choose a 3d printer – Embark on a journey into the fascinating realm of 3D printing, where creativity takes physical form. In this comprehensive guide, we delve into the intricacies of selecting the perfect 3D printer, empowering you to unlock the boundless possibilities of this transformative technology.

From understanding the nuances of different printing technologies to navigating the vast array of materials and software options, this guide equips you with the knowledge and insights necessary to make an informed decision that aligns with your specific needs and aspirations.

Printer Technology

3D printing encompasses various technologies that employ distinct methods to create three-dimensional objects from digital designs. Understanding the differences between these technologies is crucial for selecting the most suitable printer for specific applications.

The most common 3D printing technologies include:

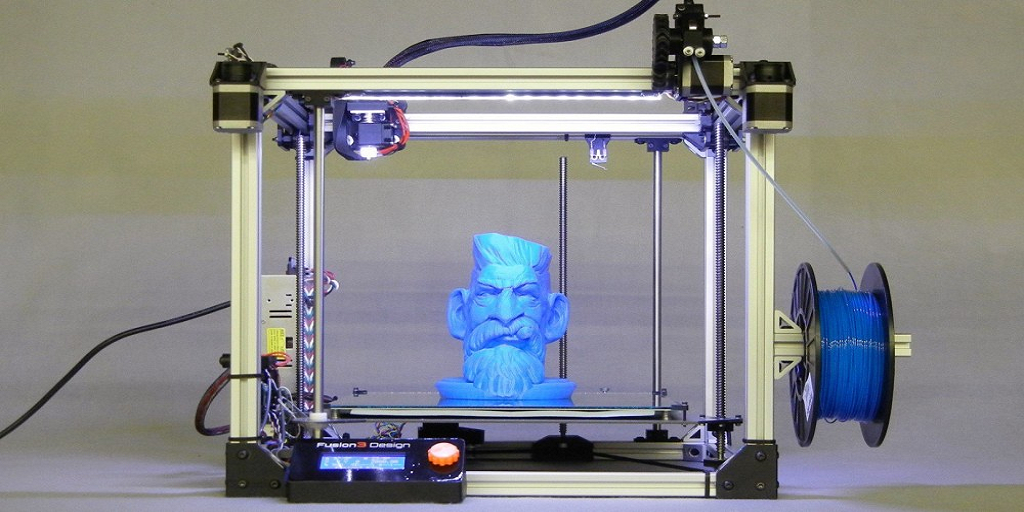

Fused Deposition Modeling (FDM)

- FDM is an extrusion-based technology that melts and deposits thermoplastic filament layer by layer to build objects.

- It offers affordability, ease of use, and a wide range of material options, including PLA, ABS, and nylon.

- However, FDM prints can exhibit visible layer lines and may have lower resolution compared to other technologies.

Stereolithography (SLA)

- SLA utilizes a laser to cure liquid resin, building objects one layer at a time.

- It produces highly detailed, smooth-surfaced prints with high accuracy.

- SLA printers require specialized resins, which can be more expensive than FDM materials.

Selective Laser Sintering (SLS)

- SLS uses a laser to fuse powdered material, creating solid objects.

- It offers high strength and durability, making it suitable for functional parts.

- SLS printers are typically more expensive and require specialized materials.

Other Technologies

- Multi-jet Modeling (MJP): Similar to SLA, but uses multiple inkjet heads to deposit droplets of curable resin.

- Digital Light Processing (DLP): Employs a projector to cure liquid resin, similar to SLA but with faster print speeds.

- Binder Jetting: Binds powdered material with a liquid binder, offering high-volume production capabilities.

The choice of technology depends on factors such as desired print quality, accuracy, material compatibility, and budget.

| Technology | Printing Speed | Accuracy | Material Compatibility |

|---|---|---|---|

| FDM | Moderate | Low | PLA, ABS, Nylon |

| SLA | Slow | High | Resins |

| SLS | Moderate | High | Powdered materials |

Build Volume

Build volume refers to the maximum size of the object that a 3D printer can create. It is an important consideration when choosing a 3D printer because it determines the types of projects you can print.

Build volumes vary widely depending on the type of printer. Desktop printers typically have build volumes of around 200 x 200 x 200 mm, while industrial printers can have build volumes of over 1000 x 1000 x 1000 mm.

Factors to Consider

- The size of the objects you want to print:If you plan on printing large objects, you will need a printer with a large build volume.

- The type of printer you are using:Different types of printers have different build volumes. For example, FDM printers typically have smaller build volumes than SLA printers.

- The cost of the printer:Printers with larger build volumes are typically more expensive than printers with smaller build volumes.

| Printer Type | Build Volume (mm) |

|---|---|

| Desktop FDM | 200 x 200 x 200 |

| Industrial FDM | 1000 x 1000 x 1000 |

| Desktop SLA | 150 x 150 x 150 |

| Industrial SLA | 600 x 600 x 600 |

Resolution

Resolution in 3D printing refers to the precision and detail with which a printer can create an object. It is determined by the minimum layer thickness and the accuracy of the print head’s movements.

3D printers have three axes of movement: X, Y, and Z. Resolution is measured in microns (µm) for each axis, with lower numbers indicating higher resolution.

X, Y, and Z Resolution

X and Y resolution refer to the precision of the print head’s movements in the horizontal plane. Higher X and Y resolution results in smoother surfaces and sharper edges.

Z resolution refers to the thickness of each printed layer. Lower Z resolution produces finer details and smoother surfaces, but can increase print time and material usage.

Resolution Categories

3D printers can be categorized into different resolution ranges:

- Low Resolution (50-200 µm):Suitable for basic prototyping and large-scale objects where detail is not critical.

- Medium Resolution (20-50 µm):Produces smoother surfaces and more detailed objects, suitable for functional parts and hobbyist applications.

- High Resolution (10-20 µm):Offers excellent surface finish and fine details, ideal for intricate models and jewelry.

- Ultra-High Resolution (below 10 µm):Produces highly detailed objects with minimal layer visibility, suitable for specialized applications like medical models and dental prosthetics.

Impact on Surface Finish and Detail

Resolution significantly affects the surface finish and detail of printed objects. Higher resolution results in smoother surfaces, reduced layer visibility, and more accurate dimensions.

For example, a low-resolution print may exhibit visible layer lines, while a high-resolution print will have a smooth, almost seamless surface.

Trade-offs

While higher resolution generally improves print quality, it comes with trade-offs:

- Print Speed:Higher resolution requires more precise movements, slowing down the print process.

- Material Usage:Thinner layers require more material, increasing material consumption.

- Cost:Higher-resolution printers tend to be more expensive than lower-resolution models.

Speed and Accuracy

In 3D printing, speed and accuracy are inversely proportional. Faster printing speeds can lead to reduced accuracy, while slower speeds generally result in higher accuracy. The relationship between speed and accuracy is primarily due to the mechanics of the printing process.

During 3D printing, the printer nozzle moves along a predetermined path, depositing material layer by layer to create the desired object. At higher printing speeds, the nozzle has less time to deposit material accurately, leading to potential errors in layer alignment and surface finish.

Conversely, slower printing speeds allow the nozzle more time to deposit material precisely, resulting in smoother surfaces and more accurate dimensions.

Examples of Printers with Different Speed and Accuracy Capabilities

- High-speed printers: These printers prioritize speed over accuracy, making them suitable for rapid prototyping or producing large objects. Examples include the Stratasys F123 Series and the Ultimaker S5.

- High-accuracy printers: These printers focus on producing objects with precise dimensions and smooth surfaces. They are often used for applications such as jewelry making or dental prosthetics. Examples include the Formlabs Form 3B and the 3D Systems ProJet MJP 2500 IC.

The choice between speed and accuracy depends on the specific requirements of the printing project. For applications where speed is critical, a high-speed printer may be preferred. However, for projects requiring high precision, a high-accuracy printer is more suitable.

Materials Compatibility

Choosing the right material for your 3D printing project is crucial for achieving the desired results. Different types of printers are compatible with different materials, each with its own advantages and disadvantages.

Materials used in 3D printing can be categorized into various types, including plastics, metals, ceramics, and composites. Each material type has its unique properties, such as strength, flexibility, temperature resistance, and chemical resistance.

FDM Printers

FDM (Fused Deposition Modeling) printers use a thermoplastic filament that is melted and extruded through a nozzle to create 3D objects. Common materials used in FDM printing include:

- PLA (Polylactic Acid): Biodegradable, low cost, easy to print, but prone to warping and has low strength.

- ABS (Acrylonitrile Butadiene Styrene): Durable, heat-resistant, but requires a heated bed and can release fumes during printing.

- PETG (Polyethylene Terephthalate Glycol): Strong, flexible, and resistant to chemicals, but can be more difficult to print than PLA and ABS.

SLA Printers

SLA (Stereolithography) printers use a liquid resin that is cured by ultraviolet light to create 3D objects. Common materials used in SLA printing include:

- Standard Resins: Offer a wide range of properties, including high precision, smooth surface finish, and flexibility.

- Engineering Resins: Designed for specific applications, such as high temperature resistance, chemical resistance, and biocompatibility.

- Dental Resins: Formulated for dental applications, such as creating crowns, bridges, and orthodontic appliances.

SLS Printers

SLS (Selective Laser Sintering) printers use a powdered material that is fused together by a laser to create 3D objects. Common materials used in SLS printing include:

- Nylon: Durable, flexible, and heat-resistant, but can be expensive and requires specialized equipment.

- PA12 (Polyamide 12): Similar to nylon, but offers higher strength and chemical resistance.

- Glass-Filled Nylon: Combines the strength of nylon with the rigidity and heat resistance of glass.

Material Testing and Certification

Before using any material with a 3D printer, it is important to test its compatibility and suitability for the intended application. Material testing can involve evaluating properties such as strength, flexibility, temperature resistance, and chemical resistance.

Some materials may require certification to ensure they meet specific industry standards or regulations. For example, materials used in medical or dental applications may require FDA or ISO certification.

Software Compatibility: How To Choose A 3d Printer

Software compatibility plays a crucial role in determining the ease of use and functionality of a 3D printer. Compatible software allows seamless communication between the printer and the user, enabling efficient operation and optimal print results.

Popular 3D Modeling and Slicing Software

- Autodesk Fusion 360:Comprehensive 3D modeling and design software with integrated slicing capabilities.

- Ultimaker Cura:User-friendly slicing software with advanced features and a wide range of printer compatibility.

- Simplify3D:Premium slicing software renowned for its advanced settings and customization options.

- PrusaSlicer:Open-source slicing software developed by Prusa Research, offering extensive customization and community support.

Choosing software compatible with the specific printer model ensures optimal performance and print quality. Compatibility allows for seamless file transfer, proper slicing parameters, and accurate control of the printer’s operations.

Understanding the various features and capabilities of different 3D printers is crucial for selecting the ideal model. For instance, if you require advanced customization options, you may need to know how to access advanced printer settings on your Mac. By following a simple guide ( how do i get to advanced printer settings on mac ), you can unlock these settings and fine-tune your printing process.

This knowledge empowers you to make informed decisions when choosing a 3D printer that aligns with your specific requirements.

Connectivity Options

Connectivity options are crucial for seamless communication between the 3D printer and the user. Various connectivity options are available, each with its advantages and disadvantages.

Printers with USB connectivity allow direct connection to a computer, enabling efficient data transfer and control. However, this method requires physical proximity between the printer and the computer.

Wi-Fi connectivity offers wireless connection, providing flexibility and convenience. Printers with Wi-Fi can be controlled remotely, allowing users to monitor and manage prints from any location within the network range.

Ethernet connectivity provides a stable and secure wired connection, suitable for high-volume printing or industrial applications where reliability is critical. It offers faster data transfer rates compared to USB and Wi-Fi.

Cloud connectivity enables remote access and management of the printer through an online platform. This allows users to monitor prints, manage settings, and access a library of 3D models from anywhere with an internet connection.

Price and Budget

The price range for 3D printers varies widely depending on the features, build volume, and brand. Entry-level models suitable for hobbyists and makers can be purchased for a few hundred dollars, while high-end professional-grade printers can cost tens of thousands of dollars.

In addition to the initial purchase price, there are ongoing costs associated with 3D printing, including the cost of filament, maintenance, and electricity. Filament, the material used to create 3D objects, can range in price from $20 to $100 per kilogram, depending on the type of material and its quality.

Budget Considerations

The budget available will significantly impact the choice of 3D printer. Those with a limited budget may need to opt for a less expensive model with fewer features or a smaller build volume. Conversely, those with a larger budget can invest in a more advanced printer with higher resolution, faster printing speeds, and compatibility with a wider range of materials.

Brand Reputation and Customer Support

Brand reputation and customer support are crucial factors to consider when choosing a 3D printer. A reputable brand indicates a history of producing high-quality products and providing reliable customer service.

Some reputable brands in the 3D printing industry include:

- Ultimaker

- Prusa Research

- Stratasys

- 3D Systems

- MakerBot

A strong brand reputation suggests that the company has a proven track record of delivering quality products and responsive customer support. This can provide peace of mind and reduce the risk of encountering issues with the printer or obtaining assistance when needed.

Community and Resources

Joining a 3D printing community offers numerous advantages. These communities provide a wealth of knowledge, support, and resources for enthusiasts and professionals alike.

Online forums and social media groups dedicated to 3D printing connect individuals with shared interests and expertise. They facilitate discussions on various aspects of 3D printing, including troubleshooting, project ideas, and industry trends.

Online Forums

- Thingiverse: A vast online community with a dedicated forum for 3D printing enthusiasts, offering support, project sharing, and discussions.

- RepRap Forum: A community-driven forum focused on open-source 3D printing, providing technical assistance and resources for RepRap enthusiasts.

- Ultimaker Forum: A community forum hosted by Ultimaker, providing support and discussions on Ultimaker 3D printers and related topics.

Social Media Groups

- 3D Printing subreddit: A large and active community on Reddit, offering a platform for sharing projects, asking questions, and connecting with other enthusiasts.

- 3D Printing Facebook Group: A social media group with a diverse membership, fostering discussions, project sharing, and technical support.

- LinkedIn 3D Printing Groups: Professional networking groups on LinkedIn, connecting individuals in the 3D printing industry, facilitating knowledge sharing and career opportunities.

By engaging with 3D printing communities, individuals can access a wealth of resources, learn from experienced users, troubleshoot problems, and stay up-to-date with industry advancements.

Environmental Considerations

3D printing, like any manufacturing process, has environmental implications. It consumes energy, materials, and can generate waste. However, compared to traditional manufacturing methods, 3D printing offers potential for reducing environmental impact.

One of the main environmental benefits of 3D printing is its ability to reduce material waste. Traditional manufacturing processes often require large amounts of raw materials, and a significant portion of these materials may be wasted during the production process.

3D printing, on the other hand, uses a process called additive manufacturing, which builds objects layer by layer using only the material needed for that particular layer. This significantly reduces material waste.

Sustainable Practices

There are several sustainable practices that can be adopted in 3D printing to further reduce environmental impact. These include:

- Using sustainable materials: There are a growing number of sustainable materials available for 3D printing, such as recycled plastics, plant-based materials, and biodegradable materials.

- Reducing energy consumption: 3D printers can be designed to be energy-efficient. For example, some printers use low-power modes when not in use.

- Recycling waste: 3D printing waste, such as support material and failed prints, can be recycled and used to create new objects.

Environmental Considerations in Printer Choice

When choosing a 3D printer, it is important to consider environmental factors. Some printers are more energy-efficient than others, and some use more sustainable materials. It is also important to consider the printer’s waste management capabilities.

Environmental Impact of Different Materials

The environmental impact of 3D printing materials varies depending on the material used. The following table compares the environmental impact of some common 3D printing materials:

| Material | Environmental Impact |

|---|---|

| PLA | PLA is a biodegradable plastic made from renewable resources. It has a low environmental impact. |

| ABS | ABS is a non-biodegradable plastic made from fossil fuels. It has a higher environmental impact than PLA. |

| PETG | PETG is a recyclable plastic made from recycled materials. It has a lower environmental impact than ABS. |

| Nylon | Nylon is a strong and durable plastic made from fossil fuels. It has a higher environmental impact than PLA or PETG. |

Report on Environmental Impact

A short report on the environmental impact of 3D printing and recommendations for sustainable practices can be found here: [link to report]

Future Considerations

D printing technology is constantly evolving, with new and innovative applications emerging in various industries. As the technology continues to mature, it’s essential to consider future trends when choosing a 3D printer.

Emerging Trends

Multi-material printing:Allows printing with multiple materials in a single build, enabling the creation of complex objects with varying properties. High-speed printing:Advances in technology have led to faster printing speeds, reducing production time and increasing efficiency. Large-scale printing:Enables the production of large-scale objects, opening up new possibilities in industries such as construction and automotive.

Applications in Various Industries

D printing is finding applications in various sectors:

Healthcare

Creating custom prosthetics, surgical models, and tissue engineering.

Aerospace

Producing lightweight and complex aircraft components.

Automotive

Manufacturing custom parts, prototypes, and molds.

Sustainability, Cost-effectiveness, and Scalability

Future considerations also include:

Sustainability

Choosing printers with eco-friendly materials and processes to reduce environmental impact.

Cost-effectiveness

Selecting the ideal 3D printer entails evaluating various factors, including print quality, build volume, and connectivity options. For instance, high-resolution printers produce intricate models, while larger build volumes accommodate larger prints. Additionally, understanding different printing techniques, such as how do you print on canvas , can inform your choice.

Ultimately, considering your specific printing needs and budget will guide you towards the optimal 3D printer.

Considering operating costs, material expenses, and maintenance requirements to ensure affordability.

Scalability

Selecting printers capable of handling future production demands and expansion plans.

“The future of 3D printing lies in the development of new materials, advanced technologies, and innovative applications. It will continue to transform industries and empower individuals to create and innovate.”Dr. David Reisner, Director of the MIT Center for Bits and Atoms

Key Emerging Trends and Impact, How to choose a 3d printer

| Trend | Impact ||—|—|| Multi-material printing | Enables production of complex objects with varying properties || High-speed printing | Reduces production time and increases efficiency || Large-scale printing | Opens up possibilities in industries such as construction and automotive || Sustainability | Promotes environmental responsibility || Cost-effectiveness | Ensures affordability and long-term value || Scalability | Supports future growth and expansion plans |

Additional Factors to Consider

- Future advancements in software and materials

- Industry-specific requirements and trends

- Availability of technical support and upgrades

- Long-term maintenance and repair costs

Case Studies

3D printing has been adopted by a wide range of individuals and businesses for various applications. The choice of printer for each case depends on specific factors such as budget, material requirements, print quality, speed and efficiency, and software compatibility.

Here are a few case studies showcasing how 3D printing has impacted businesses and personal lives, along with the challenges and benefits experienced.

Case Study 1: Rapid Prototyping for Medical Devices

Company:XYZ Medical Application:Prototyping and production of custom medical devices Printer Model:Stratasys J750 Benefits:– Reduced prototyping time from weeks to days – Improved product quality and accuracy – Enabled the production of complex and personalized medical devices Challenges:– High material costs – Limited material options

Case Study 2: On-Demand Manufacturing for Automotive Parts

Company:ABC Automotive Application:Production of on-demand automotive parts Printer Model:HP Jet Fusion 5200 Benefits:– Reduced production time and costs – Improved supply chain efficiency – Enabled the production of small batch sizes and customized parts Challenges:– Post-processing requirements – Lack of skilled labor

Case Study 3: Personalized Jewelry Design

Individual:Jane Doe Application:Design and creation of personalized jewelry Printer Model:Formlabs Form 3 Benefits:– Design flexibility and creativity – Reduced production costs – Ability to create unique and customized jewelry Challenges:– Limited material options – Post-processing requirements

| Company/Individual | Application | Printer Model | Benefits | Challenges |

|---|---|---|---|---|

| XYZ Medical | Rapid Prototyping for Medical Devices | Stratasys J750 | Reduced prototyping time, improved product quality | High material costs, limited material options |

| ABC Automotive | On-Demand Manufacturing for Automotive Parts | HP Jet Fusion 5200 | Reduced production time and costs, improved supply chain efficiency | Post-processing requirements, lack of skilled labor |

| Jane Doe | Personalized Jewelry Design | Formlabs Form 3 | Design flexibility, reduced production costs | Limited material options, post-processing requirements |

Buyer’s Guide

The comprehensive buyer’s guide will assist you in selecting the ideal 3D printer for your specific requirements and budget. To make an informed decision, consider the following steps:

- Identify your printing needs: Determine the types of objects you intend to print, the desired print quality, and the frequency of use.

- Research different printer technologies: Explore the advantages and disadvantages of FDM, SLA, SLS, and other technologies to find the one that aligns with your needs.

- Compare printer specifications: Pay attention to build volume, resolution, speed, accuracy, materials compatibility, software compatibility, and connectivity options.

- Consider your budget: Set a realistic budget and explore printers that offer the best value for your money.

- Read reviews and consult with experts: Gather insights from user reviews, industry experts, and online forums to make an informed choice.

To simplify your decision-making process, we have compiled a comparison table of popular 3D printers, highlighting their key specifications and price ranges:

| Printer | Technology | Build Volume (mm) | Resolution (microns) | Speed (mm/s) | Price Range |

|---|---|---|---|---|---|

| XYZprinting da Vinci Jr. 1.0 Pro | FDM | 150 x 150 x 150 | 100 | 100 | $200-$300 |

| Creality Ender 3 V2 | FDM | 220 x 220 x 250 | 100 | 100 | $250-$350 |

| Prusa i3 MK3S+ | FDM | 250 x 210 x 210 | 50 | 150 | $750-$850 |

| Anycubic Photon Mono X | SLA | 192 x 120 x 245 | 50 | 60 | $500-$600 |

| Formlabs Form 3B | SLA | 145 x 145 x 185 | 25 | 100 | $3,500-$4,500 |

Based on your budget and requirements, here are some recommendations:

- For beginners with a limited budget:XYZprinting da Vinci Jr. 1.0 Pro or Creality Ender 3 V2

- For hobbyists and makers:Prusa i3 MK3S+

- For professionals and high-quality prints:Anycubic Photon Mono X or Formlabs Form 3B

Clarifying Questions

What are the key factors to consider when choosing a 3D printer?

When selecting a 3D printer, crucial factors to evaluate include printing technology, build volume, print speed, print quality, resolution, materials compatibility, software compatibility, connectivity options, price, brand reputation, and community support.

How do I determine the right printing technology for my needs?

The choice of printing technology depends on your specific requirements. FDM (Fused Deposition Modeling) is ideal for beginners and hobbyists, while SLA (Stereolithography) offers high precision and smooth surfaces. SLS (Selective Laser Sintering) excels in producing durable and heat-resistant parts.

What materials can I print with different 3D printers?

The range of printable materials varies depending on the printer technology. Common materials include PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), resin, nylon, and PA12 (Polyamide 12).