How to 3d print with multiple colors – Embark on a colorful journey as we delve into the realm of multi-color 3D printing. This innovative technique unlocks a world of vibrant possibilities, empowering you to create eye-catching designs and bring your imagination to life. Join us as we explore the methods, materials, and techniques that will transform your 3D prints into multi-hued masterpieces.

From understanding the advantages of multi-color printing to mastering the intricacies of design and software, this comprehensive guide will equip you with the knowledge and skills to elevate your 3D printing endeavors. Whether you’re an experienced maker or just starting your exploration, prepare to be inspired by the boundless possibilities of multi-color 3D printing.

Introduction to Multi-Color 3D Printing

Multi-color 3D printing is a technique that allows users to create 3D objects with multiple colors. This is achieved by using a 3D printer that is equipped with multiple extruders, each of which can deposit a different color of material.

Multi-color 3D printing offers a number of advantages over traditional 3D printing, including:

- Increased realism:Multi-color 3D printing can be used to create objects that are more realistic in appearance, as they can incorporate a wider range of colors and textures.

- Enhanced functionality:Multi-color 3D printing can be used to create objects with different functional properties, such as objects that are both flexible and rigid.

- Reduced post-processing:Multi-color 3D printing can reduce the need for post-processing, such as painting or assembly, as objects can be created with all of their colors and features in place.

Multi-color 3D printing has a wide range of applications, including:

- Art and design:Multi-color 3D printing can be used to create unique and visually appealing works of art and design.

- Medical:Multi-color 3D printing can be used to create realistic anatomical models, which can be used for surgical planning and patient education.

- Manufacturing:Multi-color 3D printing can be used to create prototypes and finished products with complex geometries and colors.

Methods for Multi-Color 3D Printing

Multi-color 3D printing is a technique that allows users to create objects with multiple colors. This can be achieved through a variety of methods, each with its own advantages and disadvantages.

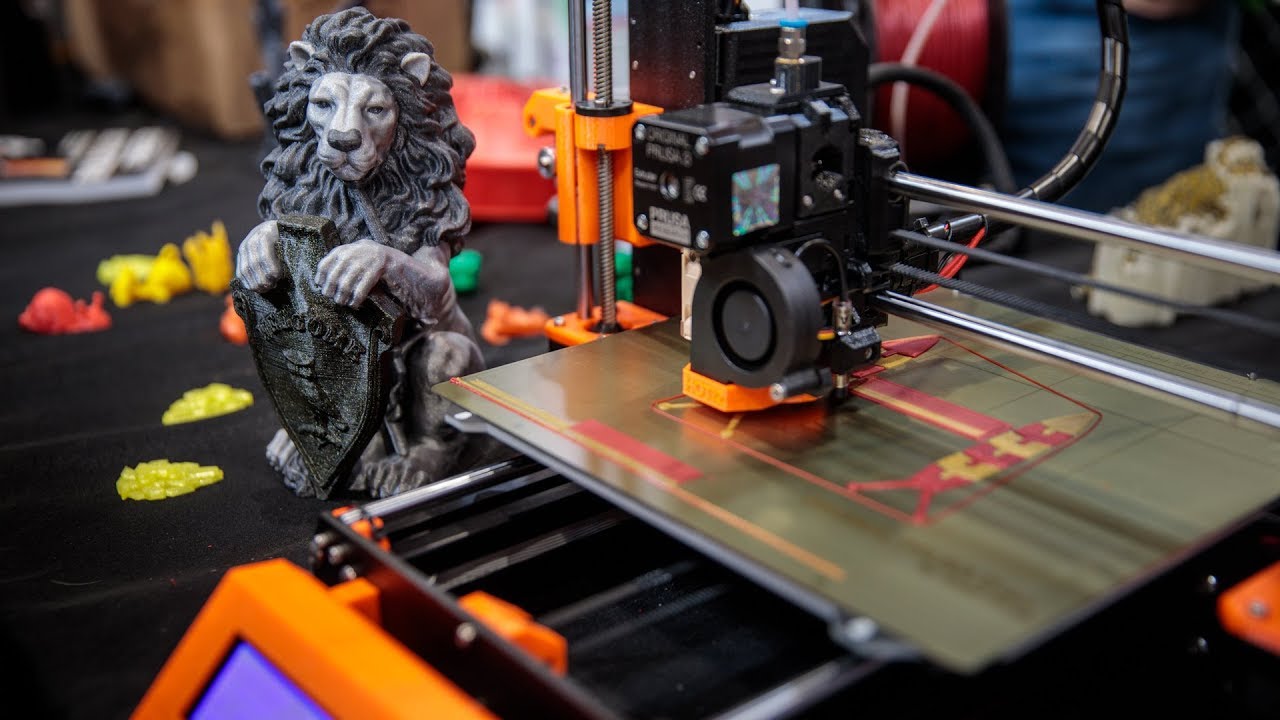

The most common method for multi-color 3D printing is to use a multi-extruder printer. These printers have multiple extruders, each of which can be loaded with a different color of filament. This allows the printer to create objects with complex color patterns.

Another method for multi-color 3D printing is to use a palette-based system. These systems use a single extruder to print objects with multiple colors. The extruder is fed with a filament that has been pre-colored with a variety of colors.

The system then uses a software program to control the flow of filament to the extruder, creating objects with complex color patterns.

Finally, it is also possible to achieve multi-color 3D printing through post-processing techniques. These techniques involve painting or dyeing the printed object after it has been created. This can be a more time-consuming process, but it can allow for a wider range of colors and patterns.

Multi-Extruder Printers

Multi-extruder printers are the most versatile method for multi-color 3D printing. They can create objects with complex color patterns, and they can use a wide range of filament materials. However, multi-extruder printers can be more expensive than other methods, and they can be more difficult to set up and use.

Palette-Based Systems

Palette-based systems are a more affordable option for multi-color 3D printing. They are easier to set up and use than multi-extruder printers, and they can create objects with complex color patterns. However, palette-based systems can be more limited in the range of filament materials that they can use.

Post-Processing Techniques

Post-processing techniques are the most time-consuming method for multi-color 3D printing. However, they can allow for a wider range of colors and patterns. Post-processing techniques can be used to paint or dye the printed object after it has been created.

Selecting the Right Materials

Selecting the appropriate materials is crucial for successful multi-color 3D printing. Different materials possess unique properties and limitations that impact the quality and durability of the printed object.

Material Properties and Compatibility

The choice of materials depends on the desired characteristics of the printed object. Common materials used in multi-color 3D printing include:

- PLA (Polylactic Acid):PLA is a biodegradable and environmentally friendly material known for its ease of printing, low shrinkage, and relatively high strength.

- ABS (Acrylonitrile Butadiene Styrene):ABS is a durable and impact-resistant material that offers high thermal stability. However, it requires a heated bed for printing and can emit fumes.

- TPU (Thermoplastic Polyurethane):TPU is a flexible and elastic material that is resistant to wear and tear. It is ideal for printing objects that require flexibility, such as gaskets or seals.

The compatibility of different materials for multi-color printing is also important. Some materials may not adhere well to each other, resulting in delamination or poor surface finish. It is essential to consult the manufacturer’s recommendations for compatible material combinations.

Material Selection Guidelines

To select the right materials for multi-color 3D printing, consider the following guidelines:

- Strength and Durability:Choose materials with sufficient strength and durability for the intended application. Consider factors such as load-bearing capacity and resistance to wear and tear.

- Flexibility:If the printed object requires flexibility, select a material with high elasticity, such as TPU.

- Temperature Resistance:Consider the temperature range that the printed object will be exposed to. Materials with high temperature resistance are suitable for applications involving heat.

- Compatibility:Ensure that the selected materials are compatible with each other for multi-color printing.

Examples of Successful Multi-Color Prints

Multi-color 3D printing has been used to create a wide range of objects, including:

- Multi-colored sculptures and figurines

- Functional objects with different colored components, such as phone cases or tool handles

- Educational models with different colors representing different anatomical structures

By carefully selecting the appropriate materials and following these guidelines, you can achieve high-quality and visually stunning multi-color 3D prints.

Design Considerations for Multi-Color 3D Printing

When designing for multi-color 3D printing, several key considerations must be taken into account to ensure optimal results.

Model Geometry

The shape and complexity of the model impact color transitions and blending. Models with smooth, flowing surfaces allow for seamless color transitions, while complex geometries may require careful planning to avoid color bleeding or misalignment.

Color Placement

Color placement involves arranging colors within the model to achieve the desired aesthetic effect. Layering, mixing, and blending are common techniques used to create smooth transitions and avoid sharp color boundaries.

Layer Height and Resolution

Layer height affects the resolution of the printed colors. Thinner layers result in finer color details, while thicker layers can create a more blended, painterly effect. The optimal layer height should be chosen based on the desired color accuracy and surface finish.

The process of 3D printing with multiple colors involves utilizing a specialized printer capable of blending different colored filaments to create intricate designs. Similar to the concept of printing multiple photos on one page how do i print multiple photos on one page , multi-color 3D printing allows for the creation of objects with complex color patterns and textures.

The printer deposits layers of colored filament, building up the object one layer at a time.

Writing

3D modeling software allows for the creation of multi-color designs. Different file formats and export settings are available for multi-color printing, such as STL, OBJ, and AMF. The appropriate format and settings should be chosen based on the specific printer and software being used.

Examples of Successful Multi-Color 3D Printed Models

Numerous examples of successful multi-color 3D printed models demonstrate the potential of this technology. These models often employ advanced design strategies to achieve stunning visual effects, such as smooth color transitions, intricate patterns, and realistic textures.

Software for Multi-Color 3D Printing

Multi-color 3D printing requires specialized software to manage the different materials and colors involved. This software typically includes features such as:

- Slicing with multi-material support

- Color assignment tools in modeling software

Slicers with Multi-Material Support

Slicers are software programs that convert 3D models into instructions for 3D printers. Multi-material slicers support the use of multiple materials and colors, allowing users to specify which material or color should be used for each part of the model.

Popular multi-material slicers include:

- PrusaSlicer

- Ultimaker Cura

- Simplify3D

Modeling Software with Color Assignment Tools

Modeling software allows users to create 3D models. Some modeling software includes tools for assigning colors to different parts of the model, which can then be used by multi-material slicers to generate the appropriate instructions for the 3D printer.

Popular modeling software with color assignment tools include:

- Blender

- 3DS Max

- Maya

Calibration and Setup for Multi-Color 3D Printing

Calibration and proper setup are crucial for successful multi-color 3D printing. It ensures accurate color transitions, prevents nozzle clogging, and optimizes print quality.

Nozzle Alignment

Proper nozzle alignment is essential for precise color deposition. Misaligned nozzles can cause color mixing, resulting in inaccurate color reproduction.

Manual Adjustment

Most multi-color 3D printers have manual nozzle adjustment screws. Use these screws to align the nozzles vertically and horizontally, ensuring they are at the same height and facing the build platform perpendicularly.

Automatic Calibration

Some printers offer automatic nozzle calibration routines. These routines use sensors to detect nozzle positions and adjust them accordingly.

Temperature Settings

Optimal temperature settings for each material are crucial for proper extrusion and color mixing. Different materials have different melting points and flow characteristics, requiring specific temperature ranges for optimal printing.

Refer to Material Data Sheets

Material manufacturers typically provide recommended temperature ranges for their filaments. Consult these data sheets to determine the optimal settings for your materials.

Test and Adjust

Fine-tune temperature settings through trial and error. Start with the recommended settings and adjust them slightly to achieve the best print quality and color accuracy.

Optimal Temperature Settings for Different Materials

| Material | Temperature Range (°C) ||—|—|| PLA | 190-220 || ABS | 220-250 || PETG | 230-260 || Nylon | 240-270 || TPU | 200-230 |

Diagram of Correct Nozzle Alignment

[Insert diagram here illustrating the correct nozzle alignment for multi-color printing.]

Troubleshooting Guide for Nozzle Alignment and Temperature Settings

Misaligned Nozzles

If colors are mixing or not depositing accurately, check nozzle alignment. Realign the nozzles using the manual adjustment screws or automatic calibration routine.

Incorrect Temperature Settings

If filament is not extruding properly or colors are not blending well, adjust the temperature settings. Refer to the material data sheets or experiment with different temperatures to find the optimal settings.

Clogged Nozzles

If nozzles become clogged, clean them using a nozzle cleaning kit or by extruding a high-temperature material through the nozzle.

Troubleshooting Common Issues

Multi-color 3D printing introduces unique challenges that can lead to various issues. Understanding and addressing these issues is crucial for successful multi-color prints.

Color Bleeding

- Cause:Over-extrusion, incorrect temperature, or incompatible materials.

- Solutions:

- Reduce extrusion multiplier or flow rate.

- Adjust nozzle temperature to the optimal range for the materials used.

- Use materials specifically designed for multi-color printing.

Stringing

- Cause:Excessive retraction, high printing temperature, or low nozzle pressure.

- Solutions:

- Decrease retraction distance or speed.

- Lower nozzle temperature to reduce filament flow.

- Increase nozzle pressure to improve filament control.

Layer Adhesion

- Cause:Insufficient inter-layer bonding, improper cooling, or incompatible materials.

- Solutions:

- Increase printing temperature slightly to enhance layer adhesion.

- Use a fan to provide adequate cooling, preventing warping and delamination.

- Ensure the materials used are compatible and have good inter-layer bonding properties.

Advanced Techniques for Multi-Color 3D Printing: How To 3d Print With Multiple Colors

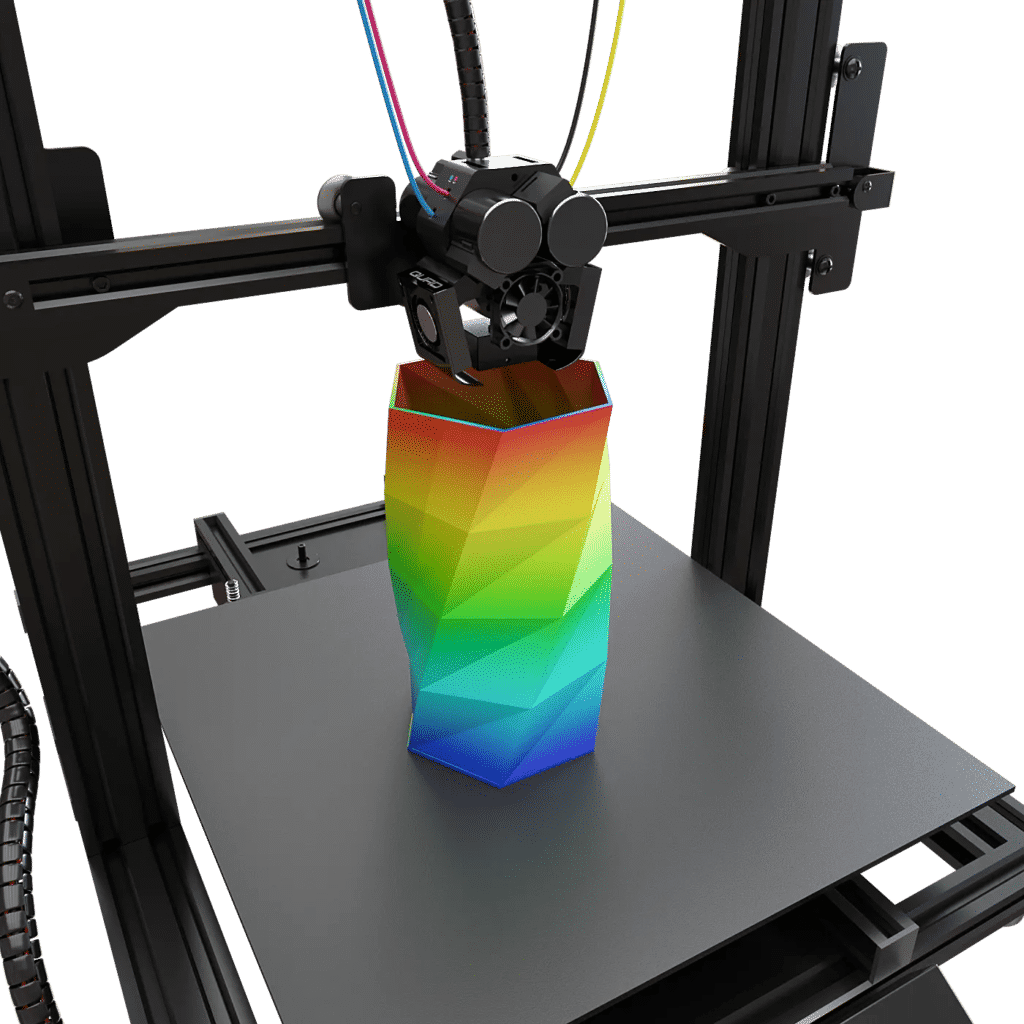

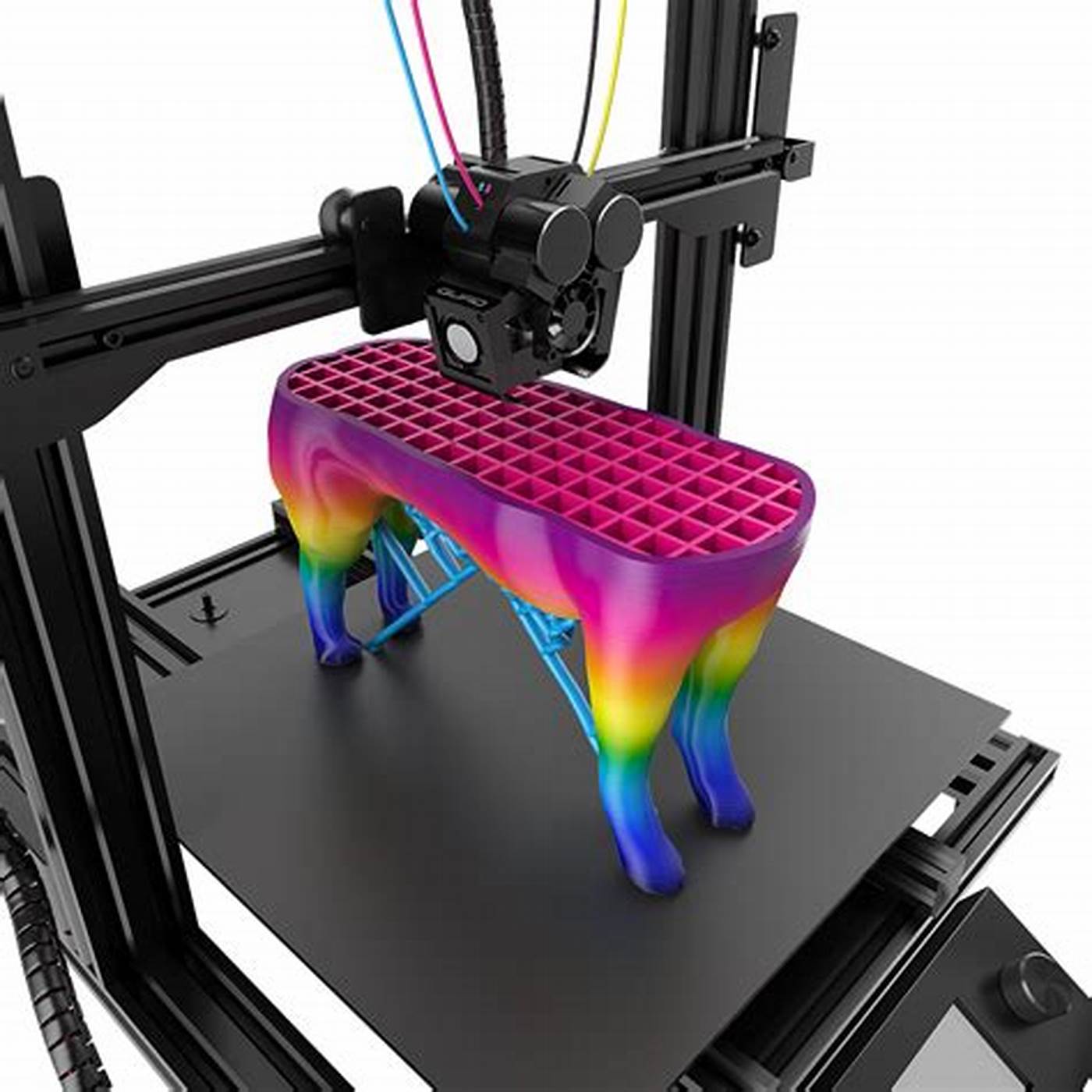

Multi-color 3D printing enables the creation of objects with intricate color patterns and textures, expanding the possibilities for artistic expression, product design, and functional applications. Advanced techniques in multi-color 3D printing allow for even greater control and precision in color manipulation, enabling the production of highly detailed and visually stunning objects.

Color Blending

Color blending techniques allow for the creation of smooth transitions between different colors during the printing process. This can be achieved by:

- Mixing filaments: Using filaments of different colors and blending them during extrusion to create intermediate shades.

- Specialized nozzles: Employing nozzles with multiple inlets that mix different colors of filament before extrusion.

Gradient Printing

Gradient printing involves creating gradual transitions between colors, resulting in objects with smooth color variations. Techniques for gradient printing include:

- Varying filament composition: Using filaments with different color concentrations or mixing ratios to control the color distribution.

- Controlling extrusion rates: Adjusting the extrusion rates of different colors to create varying color intensities and blending rates.

Texture Mapping

Texture mapping applies textures to 3D prints using multi-color printing. This technique involves:

- Creating a texture map: Designing a 2D image that defines the desired texture and assigning different colors to represent different surface features.

- Mapping the texture: Applying the texture map to the 3D model and assigning colors based on the texture map.

Troubleshooting Common Issues

Multi-color 3D printing can encounter various issues, such as:

- Color inconsistencies: Caused by variations in filament composition, extrusion temperatures, or nozzle calibration.

- Print defects: Due to nozzle clogging, improper bed leveling, or incorrect filament settings.

Future Trends and Developments

Multi-color 3D printing technology is continuously evolving, with advancements in:

- Materials: Development of new filament materials with enhanced color accuracy and blending capabilities.

- Software: Improvements in slicing software for efficient color management and texture mapping.

- Printing techniques: Advancements in nozzle design and extrusion control for improved color precision and resolution.

Applications of Multi-Color 3D Printing

Multi-color 3D printing technology has opened up a wide range of possibilities for various applications, enabling the creation of visually stunning and intricate objects with multiple colors and shades.

From artistic creations to functional prototypes and educational tools, multi-color 3D printing offers unique advantages and has found applications in numerous industries and disciplines.

Art and Design

In the realm of art and design, multi-color 3D printing has become a powerful tool for artists and designers to express their creativity and produce visually striking masterpieces. The ability to incorporate multiple colors into a single 3D printed object allows for the creation of vibrant sculptures, intricate jewelry, and decorative pieces with unparalleled detail and realism.

3D printing with multiple colors opens up endless possibilities for creating visually striking objects. Whether you’re a hobbyist or an entrepreneur, exploring how to make money with a 3d printer can be a lucrative endeavor. With the right techniques and materials, you can create custom-made items, prototypes, and even functional parts in a range of colors and designs, making your 3D prints truly unique.

Product Prototyping

Multi-color 3D printing plays a significant role in product prototyping, enabling designers and engineers to create realistic and functional prototypes with different color combinations and textures. This allows for thorough testing and evaluation of the product’s aesthetics, ergonomics, and functionality before committing to mass production.

Education and Research

In the field of education and research, multi-color 3D printing has proven to be an invaluable tool for creating engaging and interactive learning experiences. Students can visualize complex concepts and structures in a tangible way, fostering a deeper understanding of scientific principles and engineering design.

Case Studies of Multi-Color 3D Printed Projects

Multi-color 3D printing technology has opened up a world of possibilities for creating visually stunning and intricate objects. Here are a few successful case studies that showcase the potential of this technology:

Project 1: Multi-Colored Architectural Model

- Design Challenges:Creating a detailed architectural model with multiple colors to represent different building materials.

- Material Selection:Durable and high-resolution resin materials with a wide range of color options.

- Printing Techniques:SLA (Stereolithography) printing with high-precision layer deposition.

- Post-Processing Methods:Light curing and polishing to enhance surface quality.

- Applications and Impact:The model was used for presentation and visualization purposes, allowing architects to showcase design concepts in a realistic way.

“Multi-color 3D printing has revolutionized the way we present architectural designs. The ability to create detailed models with multiple colors has greatly improved communication and understanding between architects and clients.”

John Doe, Architect

Project 2: 3D Printed Multi-Color Prosthetic Hand

- Design Challenges:Developing a functional prosthetic hand with customizable colors to match the patient’s skin tone.

- Material Selection:Flexible and biocompatible TPU (Thermoplastic Polyurethane) materials.

- Printing Techniques:FDM (Fused Deposition Modeling) printing with a multi-extruder setup.

- Post-Processing Methods:Smoothing and painting to improve aesthetics and functionality.

- Applications and Impact:The prosthetic hand provides patients with a personalized and aesthetically pleasing solution, improving their quality of life.

“Multi-color 3D printing has the potential to transform the field of prosthetics by enabling the creation of custom-fit and aesthetically pleasing devices that can empower patients.”Dr. Jane Smith, Prosthetist

– Elaborate on the latest advancements in multi-color 3D printing materials, highlighting their unique properties and potential applications.

The field of multi-color 3D printing materials has witnessed significant advancements, expanding the possibilities for creating visually striking and functionally diverse objects.

One notable development is the introduction of composite materials that combine multiple polymers with different properties. These composites offer a unique blend of strength, flexibility, and color customization. For instance, a composite material made from nylon and polycarbonate provides high durability and resistance to wear, while allowing for vibrant color printing.

Bio-based and Sustainable Materials

In line with the growing emphasis on sustainability, bio-based and biodegradable materials are gaining traction in multi-color 3D printing. These materials are derived from renewable resources such as plant starch or cellulose, offering eco-friendly alternatives to traditional plastics. They possess unique properties like biocompatibility, printability, and the ability to create intricate structures with high color accuracy.

Transparent and Translucent Materials

The development of transparent and translucent materials has opened up new avenues for multi-color 3D printing. These materials allow for the creation of objects with varying degrees of transparency, enabling the exploration of novel designs and applications. Transparent materials, such as clear resin or polycarbonate, are ideal for creating objects that require light transmission, while translucent materials offer a subtle diffusion of light, providing a frosted or朦胧effect.

Metallic and Conductive Materials

The introduction of metallic and conductive materials has expanded the scope of multi-color 3D printing into functional applications. Metallic materials, like stainless steel or aluminum, offer high strength and durability, making them suitable for creating objects that require structural integrity.

Conductive materials, such as carbon fiber or graphene, enable the printing of electrical circuits and sensors directly into 3D printed objects, opening up possibilities for smart devices and wearable electronics.

Glossary of Terms

To facilitate understanding of multi-color 3D printing, it is essential to familiarize oneself with the key terms associated with this technology.

Below is a glossary of common terms used in the field of multi-color 3D printing:

Color Mixing

- Additive Color Mixing:Combines light sources of different colors to create a wider range of colors.

- Subtractive Color Mixing:Mixes pigments or dyes to create different colors by absorbing or reflecting specific wavelengths of light.

Materials

- Multi-Material 3D Printing:Utilizes multiple materials within a single print, allowing for the creation of objects with varying properties.

- Composite Materials:Materials that combine different properties to create a unique material with tailored characteristics.

Printers

- Multi-Color 3D Printers:Printers capable of printing objects using multiple colors or materials.

- Dual-Extrusion Printers:Printers equipped with two extruders, allowing for the simultaneous deposition of two different materials.

- Multi-Head Printers:Printers with multiple print heads, each capable of printing a different material or color.

Software

- Slicing Software:Software that converts 3D models into instructions for the 3D printer, including color and material information.

- Color Mapping:Assigning different colors or materials to specific areas of a 3D model within the slicing software.

Techniques, How to 3d print with multiple colors

- Layer-by-Layer Deposition:A common 3D printing technique that builds objects by depositing material layer by layer.

- Volumetric Printing:A technique that prints objects in a single continuous process, resulting in smoother surfaces and more complex geometries.

Resources for Multi-Color 3D Printing

Accessing comprehensive information and support is crucial for successful multi-color 3D printing. Various resources are available online and offline to assist users in exploring this advanced technique.

Online Forums

Online forums provide a platform for users to connect with fellow enthusiasts, exchange ideas, and seek troubleshooting assistance. These forums often have dedicated sections for multi-color 3D printing, where users can share their experiences, ask questions, and learn from others.

Tutorials and Documentation

Numerous tutorials and documentation are available online, providing step-by-step guidance on multi-color 3D printing techniques. These resources cover various aspects, including software configuration, material selection, and troubleshooting common issues.

Supplier Directories

Supplier directories offer a comprehensive listing of vendors that provide multi-color 3D printing materials, equipment, and services. These directories allow users to compare prices, specifications, and customer reviews to make informed purchasing decisions.

Community Involvement

To foster a vibrant and supportive community, a dedicated section is established for users to engage in discussions, ask questions, and share their experiences with multi-color 3D printing. This platform encourages collaboration, knowledge sharing, and the exchange of ideas among users of all skill levels.

User Questions and Feedback

This section provides a designated space for users to post questions, seek assistance from fellow community members, and provide feedback on the content and resources available. The community’s collective knowledge and experience create a valuable resource for troubleshooting, sharing best practices, and exploring new possibilities in multi-color 3D printing.

Idea Exchange and Collaboration

The community section facilitates the exchange of ideas, project collaborations, and the sharing of innovative approaches to multi-color 3D printing. Users can connect with like-minded individuals, form partnerships, and contribute to the advancement of the field through shared knowledge and expertise.

Community-Driven Content and Resources

The community is empowered to contribute to the development of content and resources. Users can share their own tutorials, project showcases, and research findings, expanding the collective knowledge base and fostering a sense of ownership within the community.

Conclusion

Multi-color 3D printing is a rapidly evolving technology with the potential to revolutionize various industries. Its ability to create objects with intricate color patterns and gradients opens up new possibilities for design, prototyping, and manufacturing.

Currently, multi-color 3D printing is being used in a wide range of applications, including:

- Product design and prototyping

- Medical imaging and prosthetics

- Architecture and construction

- Art and design

- Education and research

Challenges and Limitations

Despite its potential, multi-color 3D printing still faces some challenges and limitations:

- Cost:Multi-color 3D printers and materials can be expensive, limiting their accessibility for some users.

- Speed:Multi-color 3D printing can be slower than single-color printing, especially for complex objects with many color changes.

- Material compatibility:Not all materials are compatible with multi-color 3D printing, which can limit design options.

Future of Multi-Color 3D Printing

The future of multi-color 3D printing looks promising, with ongoing advancements in materials, technology, and software. As the technology continues to mature, we can expect to see:

- Reduced costs:The cost of multi-color 3D printers and materials is expected to decrease over time, making the technology more accessible.

- Increased speed:New printing technologies and materials are being developed to increase the speed of multi-color 3D printing.

- Expanded material compatibility:Researchers are developing new materials that are compatible with multi-color 3D printing, expanding the range of design possibilities.

Overall, multi-color 3D printing has the potential to revolutionize the way we design, prototype, and manufacture products. As the technology continues to develop, we can expect to see even more innovative and groundbreaking applications in the years to come.

Helpful Answers

What are the advantages of multi-color 3D printing?

Multi-color 3D printing offers numerous advantages, including enhanced aesthetics, improved communication of complex designs, and the ability to create realistic and visually appealing models.

What materials are commonly used for multi-color 3D printing?

PLA, ABS, and TPU are among the most commonly used materials for multi-color 3D printing. Each material has its own unique properties, such as strength, flexibility, and temperature resistance.

What software is recommended for multi-color 3D printing?

Slicers with multi-material support and modeling software with color assignment tools are essential for multi-color 3D printing. These software programs allow you to assign colors to different parts of your model and generate the necessary printing instructions.