How long to cure resin prints – Embark on a journey to master the art of curing resin prints, unlocking the secrets to achieving exceptional durability, surface quality, and dimensional accuracy. This comprehensive guide will unravel the intricacies of curing time, methods, and techniques, empowering you to transform your 3D creations into robust and visually stunning masterpieces.

Delve into the science behind curing, exploring the factors that influence the process and how to optimize them for your specific needs. Discover the different curing methods available, their advantages, and disadvantages, and learn how to choose the right one for your materials and applications.

With expert tips and troubleshooting advice, you’ll gain the knowledge and confidence to achieve perfect curing results every time.

Factors Influencing Curing Time

The curing time of resin prints is influenced by several factors, including resin type, layer thickness, ambient temperature, humidity, and UV light intensity and wavelength.

Resin Type

Different types of resins have different curing times. Standard resins typically cure faster than tough or flexible resins.

Layer Thickness

Thicker layers require longer curing times to ensure that the resin is fully cured throughout the layer.

Ambient Temperature

Higher ambient temperatures accelerate the curing process, while lower temperatures slow it down.

Humidity

High humidity can slow down the curing process by interfering with the evaporation of solvents in the resin.

UV Light Intensity and Wavelength

Higher UV light intensity and shorter wavelengths result in faster curing times.

Curing Methods

Curing is a crucial step in the 3D printing process, transforming liquid resin into solid objects. Different curing methods are available, each with unique advantages and disadvantages, and the choice of method depends on the material, application, and desired results.

Sunlight Curing

Sunlight curing utilizes the sun’s ultraviolet (UV) rays to solidify resin prints. This method is cost-effective and environmentally friendly, as it does not require specialized equipment. However, it is dependent on weather conditions and can be slow, especially during cloudy or winter months.

- Advantages: Low cost, eco-friendly, easy to implement

- Disadvantages: Slow, weather-dependent, limited control over curing parameters

- Curing time: Can vary significantly depending on sunlight intensity and print thickness

- Curing temperature: Ambient temperature

- Suitable for: Small, non-critical prints

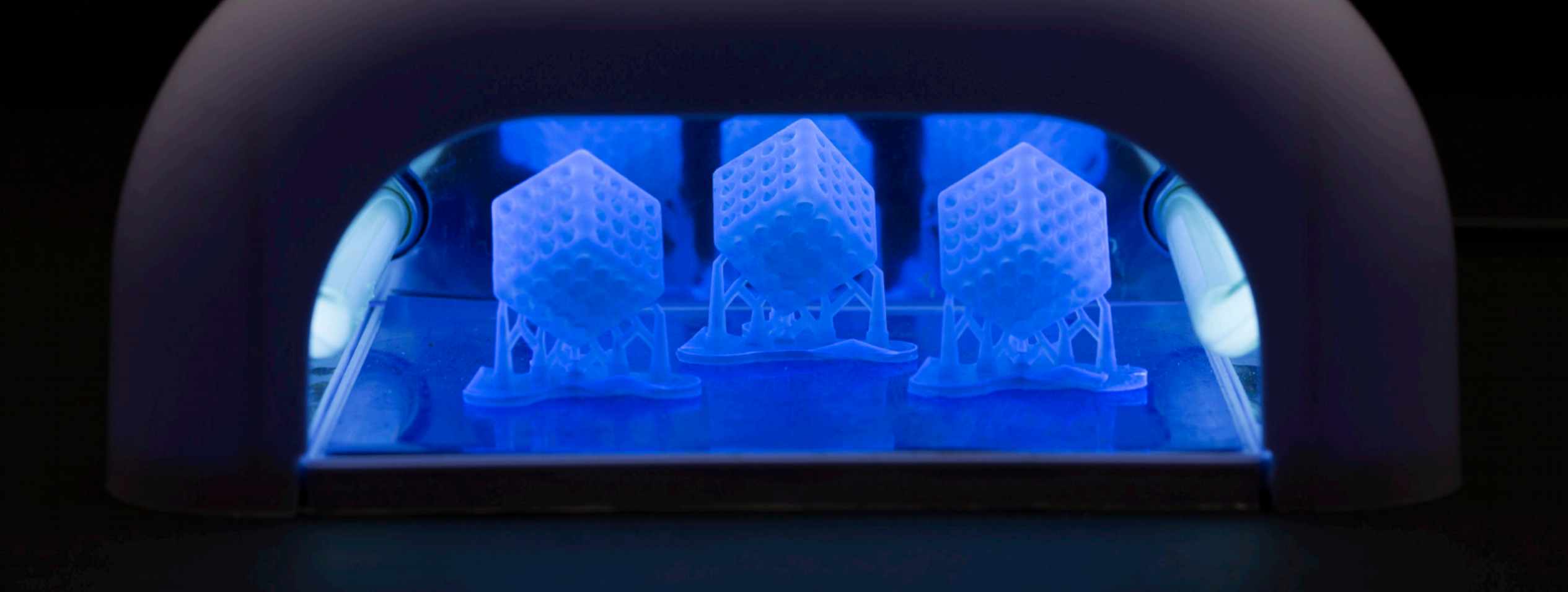

UV Lamp Curing

UV lamp curing employs dedicated UV lamps to emit UV radiation and cure resin prints. This method offers faster curing times and better control over the curing process compared to sunlight curing. However, UV lamps require specialized equipment and can be expensive to purchase and maintain.

- Advantages: Faster curing, consistent results, controllable curing parameters

- Disadvantages: Requires specialized equipment, higher cost

- Curing time: Typically a few minutes to tens of minutes

- Curing temperature: Lamp-specific, typically between 30-60°C

- Suitable for: Most resin prints, including larger and more complex objects

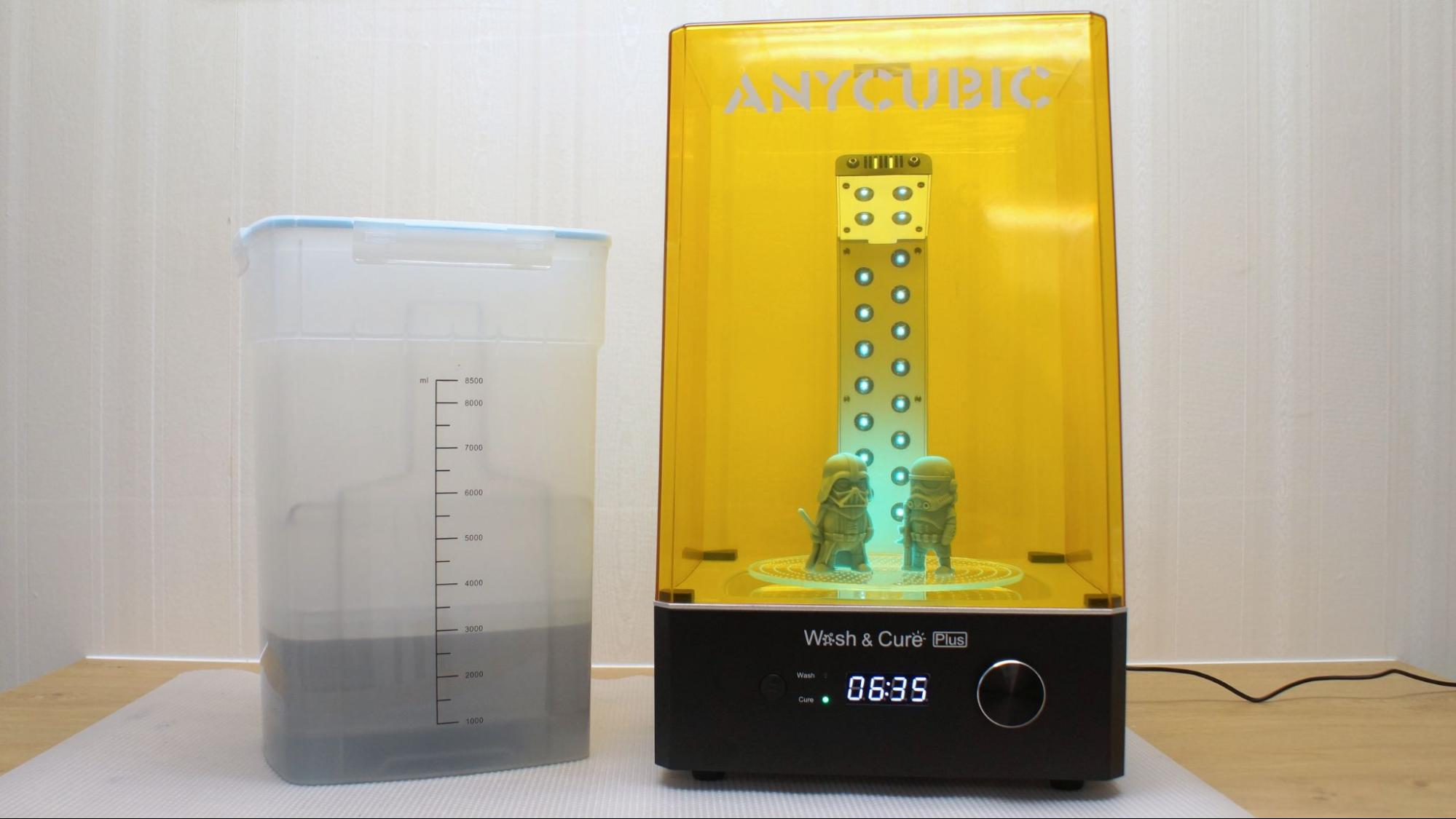

Curing Station

Curing stations are dedicated devices designed specifically for curing resin prints. They combine UV lamps with controlled temperature and rotation mechanisms to ensure uniform curing throughout the print. Curing stations provide the highest level of control and consistency, but they come with a higher price tag.

- Advantages: Fast, consistent, controlled curing, uniform results

- Disadvantages: Expensive, requires specialized equipment

- Curing time: Can vary depending on the curing station and print size

- Curing temperature: Typically adjustable, ranging from 30-80°C

- Suitable for: Critical applications, high-quality prints, large or complex objects

Choosing the Appropriate Curing Method

The choice of curing method depends on factors such as the material, print size, desired quality, and budget. For small, non-critical prints, sunlight curing can be a viable option. For faster curing times and better control, UV lamps or curing stations are recommended.

For high-quality, critical applications, curing stations offer the most precise and consistent results.

Troubleshooting Common Curing Issues

Common curing issues include undercuring, overcuring, and yellowing. Undercuring can lead to weak and brittle prints, while overcuring can make prints brittle and discolored. Yellowing can occur due to prolonged exposure to UV radiation. To avoid these issues, it is important to follow the recommended curing times and temperatures for the specific resin material being used.

Curing Time Guidelines

Determining the optimal curing time for resin prints is crucial to ensure proper polymerization and achieve the desired material properties. Several factors influence curing time, including resin type, layer thickness, and ambient temperature. This section provides guidelines for curing times based on these factors, along with tips for optimizing the process.

The table below summarizes recommended curing times for different resin types and layer thicknesses. These times are approximate and may vary depending on the specific resin and curing equipment used. It’s always advisable to refer to the manufacturer’s recommendations for the specific resin being used.

Curing Time Table

| Resin Type | Layer Thickness (µm) | Curing Time (minutes) |

|---|---|---|

| Standard Resin | 50 | 2-4 |

| Tough Resin | 100 | 4-6 |

| Flexible Resin | 50 | 6-8 |

| Dental Resin | 25 | 8-10 |

In addition to resin type and layer thickness, ambient temperature also affects curing time. Higher temperatures accelerate the curing process, while lower temperatures slow it down. The following table provides recommended curing times for various ambient temperatures:

Curing Time vs. Ambient Temperature

| Ambient Temperature (°C) | Curing Time (minutes) |

|---|---|

| 25 | Standard |

| 20 | 1.25x Standard |

| 30 | 0.75x Standard |

As a general rule, it’s advisable to err on the side of caution and cure prints for slightly longer than the recommended time. Overcuring may lead to some loss of detail but is generally preferable to undercuring, which can result in weak or brittle prints.

To optimize curing time, it’s important to use a high-quality curing lamp with the appropriate wavelength for the resin being used. The distance between the lamp and the print should also be carefully controlled to ensure even exposure. Additionally, it’s beneficial to rotate the print during curing to minimize the risk of uneven curing.

Overcuring and Undercuring

Overcuring and undercuring are two common problems that can occur during the resin printing process. Overcuring can lead to brittleness and loss of detail, while undercuring can result in stickiness and reduced strength.

There are a few things that can cause overcuring. One is using too much UV light. Another is exposing the print to UV light for too long. Finally, using a UV light that is too powerful can also lead to overcuring.

Undercuring can be caused by using too little UV light, exposing the print to UV light for too short a time, or using a UV light that is not powerful enough.

There are a few things that you can do to avoid overcuring and undercuring. First, use the recommended amount of UV light and exposure time. Second, use a UV light that is the appropriate power for the resin you are using.

Finally, monitor the print closely during the curing process to make sure that it is not over or undercured.

Tips to Avoid Overcuring and Undercuring

- Use the recommended amount of UV light and exposure time.

- Use a UV light that is the appropriate power for the resin you are using.

- Monitor the print closely during the curing process to make sure that it is not over or undercured.

Post-Curing

Post-curing is a crucial step in the 3D printing process that involves further curing the printed resin model after the initial exposure to UV light during printing. This additional curing enhances the material’s properties, leading to improved strength, reduced warping, and increased dimensional stability.

Techniques for Post-Curing

Various techniques can be employed for post-curing, including:

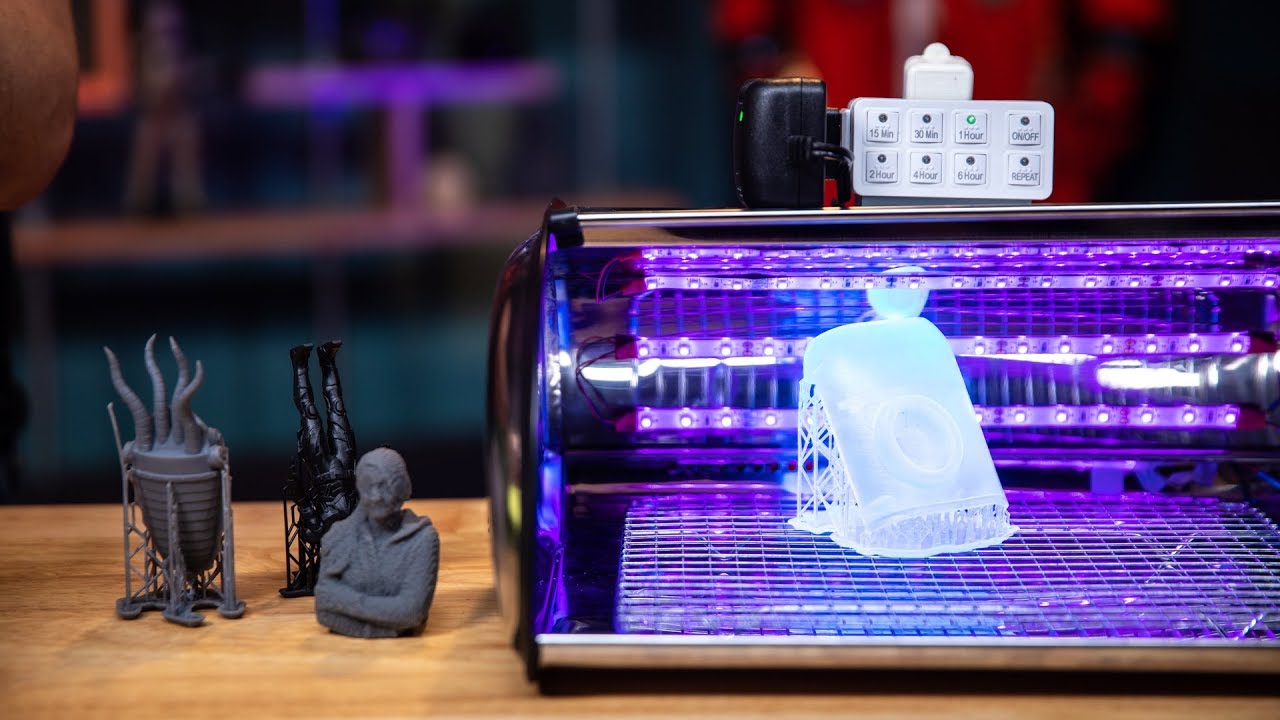

UV Curing Chamber

This dedicated device emits UV light at specific wavelengths and intensities to cure the resin model evenly.

Sunlight

Natural sunlight can also be used for post-curing, but it is less controlled and may lead to uneven curing.

Post-Curing Guidelines

The duration and temperature for post-curing vary depending on the type of resin used. Here are general guidelines:

Post-Curing Schedule Table

| Resin Type | Post-Curing Temperature | Post-Curing Time ||—|—|—|| ABS-like | 60-80°C | 2-4 hours || PLA | 50-60°C | 1-2 hours || PETG | 70-80°C | 2-3 hours |

Troubleshooting Post-Curing Issues

Warped Print

The duration of curing resin prints depends on factors such as the type of resin used, the thickness of the print, and the intensity of the UV light source. Understanding the optimal curing time helps prevent issues like warping or brittleness.

However, if you encounter streaks in your printed results, it may indicate a separate problem. Explore potential causes and solutions for printing streaks to resolve this issue. Nevertheless, proper curing remains crucial for ensuring the durability and quality of your resin prints.

If the print warps after post-curing, increase the post-curing temperature or time.

Brittle Print

If the print becomes brittle after post-curing, decrease the post-curing temperature or time.

Troubleshooting Curing Issues

Identifying and resolving curing issues is essential for successful resin printing. Common problems include uncured areas and warping, which can compromise print quality and structural integrity.

Uncured Areas

- Possible causes:Insufficient curing time, uneven exposure, or inadequate UV light intensity.

- Solutions:Increase curing time, rotate the print during curing to ensure uniform exposure, and use a higher-intensity UV light source.

Warping

- Possible causes:Excessive heat during curing, uneven shrinkage, or poor print bed adhesion.

- Solutions:Use a curing chamber with controlled temperature, cure the print in stages to minimize thermal stress, and ensure the print bed is properly leveled and clean.

Additional Troubleshooting Tips

- Inspect the print:Check for any areas that appear soft or sticky, indicating insufficient curing.

- Test the UV light source:Use a UV light meter to measure the intensity of the UV light source to ensure it meets the recommended specifications.

- Calibrate the curing machine:Follow the manufacturer’s instructions to ensure the curing time and intensity are accurately set.

Safety Considerations

The use of UV radiation in resin curing necessitates careful consideration of potential hazards and implementation of appropriate safety measures. Extended exposure to UV radiation can lead to adverse effects on the skin and eyes, warranting adherence to safety guidelines.

UV radiation, particularly in the UV-A and UV-B spectrums, can cause damage to the skin, ranging from mild sunburn to severe burns. Prolonged exposure can also lead to skin aging, wrinkles, and an increased risk of skin cancer. To mitigate these risks, it is essential to wear protective clothing, including long sleeves, pants, and gloves, when handling UV curing equipment.

Safe Handling and Disposal, How long to cure resin prints

- Always handle UV curing equipment with care, avoiding direct contact with the UV light source.

- When not in use, store UV curing equipment in a secure location away from children and pets.

- Dispose of UV curing equipment properly according to local regulations. Do not discard them in regular trash bins.

Protecting Skin and Eyes

- Wear UV-protective clothing, including long sleeves, pants, and gloves, when operating UV curing equipment.

- Use UV-blocking sunglasses or goggles to protect your eyes from harmful radiation.

- Avoid looking directly at the UV light source.

- Take breaks from UV exposure to reduce the risk of skin damage.

Advanced Curing Techniques

Advanced curing techniques offer enhanced control and performance over traditional UV curing methods, enabling the production of high-quality resin prints with improved properties and dimensional accuracy.

Vacuum Curing

Vacuum curing involves placing the resin print in a vacuum chamber, which removes air bubbles and excess uncured resin. This results in a more uniform cure, reduced shrinkage, and improved surface finish.

- Advantages:Reduced porosity, improved mechanical properties, enhanced surface quality.

- Disadvantages:Requires specialized equipment, can be time-consuming.

- Suitable for:High-precision parts, transparent or translucent prints, large or complex prints.

Heat Curing

Heat curing involves exposing the resin print to elevated temperatures, typically between 60-80°C. This accelerates the curing process, improves adhesion between layers, and enhances the material’s mechanical properties.

- Advantages:Faster curing time, improved strength and durability, reduced warping.

- Disadvantages:Requires a heat chamber or oven, can cause thermal distortion in some materials.

- Suitable for:Functional parts, structural components, prints requiring high strength or heat resistance.

Hybrid Curing

Hybrid curing combines UV curing with either vacuum or heat curing. This approach offers the benefits of both methods, resulting in a more thorough and effective cure.

- Advantages:High precision, reduced porosity, improved mechanical properties, fast curing time.

- Disadvantages:Requires specialized equipment, can be more expensive.

- Suitable for:Demanding applications, high-value parts, prints with intricate details.

Factors to Consider When Selecting an Advanced Curing Method

- Print material and its properties

- Desired surface finish and mechanical performance

- Print size and complexity

- Available equipment and resources

- Time and cost constraints

Curing for Specific Applications

The optimal curing time and method for a resin print depend on its intended application. Functional parts require thorough curing to ensure durability and strength, while decorative items may only need minimal curing to preserve their aesthetic appeal.

Guidelines for Curing Prints for Different Applications

- Functional Parts:Cure for extended periods (e.g., 10-15 minutes) using a high-intensity UV light source. Ensure complete polymerization for maximum strength and durability.

- Decorative Items:Cure for shorter durations (e.g., 5-7 minutes) using a less intense UV light source. This helps preserve fine details and prevent yellowing or warping.

- Special Applications:Consider specialized curing methods, such as post-curing in an oven or using a vacuum chamber, to enhance specific properties (e.g., heat resistance, transparency).

Case Studies of Successful Curing for Specific Applications

- Functional Parts:A 3D-printed prosthetic hand was cured for 12 minutes using a high-intensity UV light, resulting in a durable and reliable device.

- Decorative Items:A resin-printed vase was cured for 6 minutes using a moderate-intensity UV light, preserving its intricate details and vibrant colors.

- Special Applications:A resin-printed surgical tool was post-cured in an oven at 60°C for 2 hours, enhancing its heat resistance and sterilization capabilities.

Curing Equipment

UV curing equipment plays a crucial role in achieving optimal results in resin printing. Various types of UV curing lamps and curing stations are available, each with its own features, performance, and price point. Understanding the differences and making an informed decision is essential for effective post-processing.

UV curing lamps emit ultraviolet radiation within a specific wavelength range to initiate the curing process. They can be categorized into two main types: mercury-vapor lamps and LED (light-emitting diode) lamps.

Mercury-Vapor Lamps

- Traditional and widely used in UV curing applications

- Produce intense UV radiation but require a warm-up time

- Emit a broad spectrum of wavelengths, including some that may not be optimal for resin curing

- Relatively inexpensive and readily available

LED Lamps

- More energy-efficient and environmentally friendly than mercury-vapor lamps

- Emit a narrow spectrum of wavelengths specifically tailored for resin curing

- Instant start-up and no warm-up time required

- Typically more expensive than mercury-vapor lamps

Curing Stations

Curing stations provide a controlled environment for post-processing resin prints. They typically include a UV curing lamp, a turntable or rotating platform, and a timer.

- Ensure uniform exposure and prevent overcuring or undercuring

- May have additional features such as temperature control and fume extraction

- Available in various sizes and configurations to accommodate different print sizes

Recommendations

The choice of curing equipment depends on several factors, including the size and complexity of the prints, the desired curing speed, and the budget. For small to medium-sized prints, a portable UV curing lamp with a wavelength of 395-405nm is a suitable option.

For larger or more complex prints, a curing station with a turntable is recommended to ensure even exposure.

Consider the following when selecting curing equipment:

- Wavelength:Choose a lamp or curing station with a wavelength that matches the resin’s absorption spectrum.

- Power:Higher power lamps cure faster but may also increase the risk of overcuring.

- Curing area:Select a lamp or curing station with a curing area large enough for your prints.

- Features:Consider additional features such as a turntable, timer, and fume extraction.

- Price:Set a budget and compare prices from different manufacturers.

Curing Resins for Different Printers: How Long To Cure Resin Prints

The compatibility of resins with different types of 3D printers is crucial for optimal curing results. Using the correct resin ensures that the printed part will have the desired properties and will cure properly.

There are several factors to consider when choosing a resin for a specific printer, including the printer’s light source, wavelength, and intensity. The resin should be compatible with the printer’s light source and have a wavelength that is within the printer’s operating range.

The intensity of the light source should also be sufficient to cure the resin properly.

Tips for Choosing the Right Resin

- Consult the printer manufacturer’s recommendations for compatible resins.

- Consider the desired properties of the printed part, such as strength, flexibility, and color.

- Read reviews of different resins to see how they perform with specific printers.

- Test different resins to find the one that works best for your printer and application.

Curing and Resin Storage

Proper storage of uncured and cured resins is crucial to maintain their quality and prevent premature degradation. Various factors, including temperature, light, and humidity, can significantly impact resin shelf life.

Uncured Resin Storage

Uncured resins should be stored in opaque containers to protect them from light. Exposure to UV rays can initiate the curing process, leading to partial solidification and reduced resin performance. Additionally, uncured resins should be stored in a cool, dry place with minimal temperature fluctuations.

The curing time for resin prints can vary depending on the type of resin used and the thickness of the print. Generally, prints should be cured for at least 30 minutes per side. To ensure optimal curing, you can use a UV curing chamber or place the print in direct sunlight.

If you are using a network-connected printer, you may need to find its IP address to configure wireless printing settings. Click here to learn how to find the IP address of your printer. Once you have the IP address, you can enter it into the appropriate field in your printer software to establish a connection.

Extreme temperatures can alter the resin’s viscosity and reactivity, affecting its printability and curing behavior.

Cured Resin Storage

Cured resins are generally more stable than uncured resins but can still be affected by environmental conditions. To preserve the integrity of cured prints, they should be stored in a cool, dry environment away from direct sunlight. Prolonged exposure to heat or humidity can cause the prints to become brittle or warp over time.

Curing for Durability and Aesthetics

Curing time plays a crucial role in determining the durability and aesthetic appeal of resin prints. Optimal curing ensures that the prints possess the desired mechanical strength, surface finish, and dimensional stability. Understanding the influence of curing on these aspects is essential for achieving high-quality results.

Relationship between Curing Time and Durability

Longer curing times generally result in increased cross-linking density within the resin, leading to improved mechanical properties such as tensile strength, flexural strength, and impact resistance. This enhanced durability makes the prints more resistant to wear, deformation, and breakage.

Influence of Curing on Surface Finish and Appearance

Curing also affects the surface finish and appearance of resin prints. Undercuring can lead to a rough and porous surface, while overcuring can cause brittleness and yellowing. Finding the optimal curing time is crucial for achieving a smooth, glossy, and aesthetically pleasing finish.

Examples of Optimal Curing for Durability and Aesthetics

- For parts that require high strength and durability, such as functional prototypes or load-bearing components, longer curing times are recommended.

- For decorative prints or models that prioritize aesthetics, a shorter curing time may be sufficient to achieve a smooth surface and vibrant colors.

Table: Effects of Curing Time and Wavelength on Resin Properties

| Curing Time | Tensile Strength | Flexural Strength | Surface Finish |

|---|---|---|---|

| Short | Lower | Lower | Rough |

| Optimal | Higher | Higher | Smooth |

| Long | Highest | Highest | Glossy |

Flowchart for Selecting Curing Method

To guide users in selecting the appropriate curing method for their specific application, a flowchart can be developed considering factors such as the desired durability, surface finish, and available equipment.

Post-Curing Techniques to Enhance Durability and Aesthetics

Post-curing refers to additional curing steps performed after the initial curing process. Post-curing can further enhance the durability and aesthetics of resin prints by reducing internal stresses, improving surface smoothness, and enhancing color stability.

Troubleshooting Common Curing Issues

- Undercuring:Causes include insufficient curing time, low UV intensity, or blockage of UV light by uncured resin.

- Overcuring:Causes include excessive curing time, high UV intensity, or exposure to sunlight.

Commonly Asked Questions

How do I determine the optimal curing time for my resin prints?

The optimal curing time depends on factors such as resin type, layer thickness, ambient temperature, and UV light intensity. Refer to the curing time guidelines provided in this guide and experiment with different times to find what works best for your specific setup.

What are the consequences of overcuring or undercuring resin prints?

Overcuring can make prints brittle and prone to breakage, while undercuring can result in stickiness, reduced strength, and poor surface quality. Follow the recommended curing times and avoid overexposure to UV light.

What are some common troubleshooting tips for curing issues?

If your prints are warping during curing, try increasing the post-curing temperature or time. If they are becoming brittle, decrease the curing time or temperature. Ensure your curing equipment is functioning properly and that the UV light source is emitting at the correct wavelength.