How long does 3D printing take? This question delves into the heart of the 3D printing process, influencing project timelines, production efficiency, and end-product quality. Embark on a journey to uncover the factors that govern printing duration and explore strategies for optimizing it, unlocking the full potential of this transformative technology.

From object complexity and layer height to material properties and printer capabilities, we delve into the intricate interplay of these elements, unraveling their impact on printing time. Discover how optimizing printer settings, employing post-processing techniques, and leveraging advanced technologies can dramatically reduce printing duration, enabling faster prototyping, efficient manufacturing, and expedited delivery of 3D printed goods.

Introduction

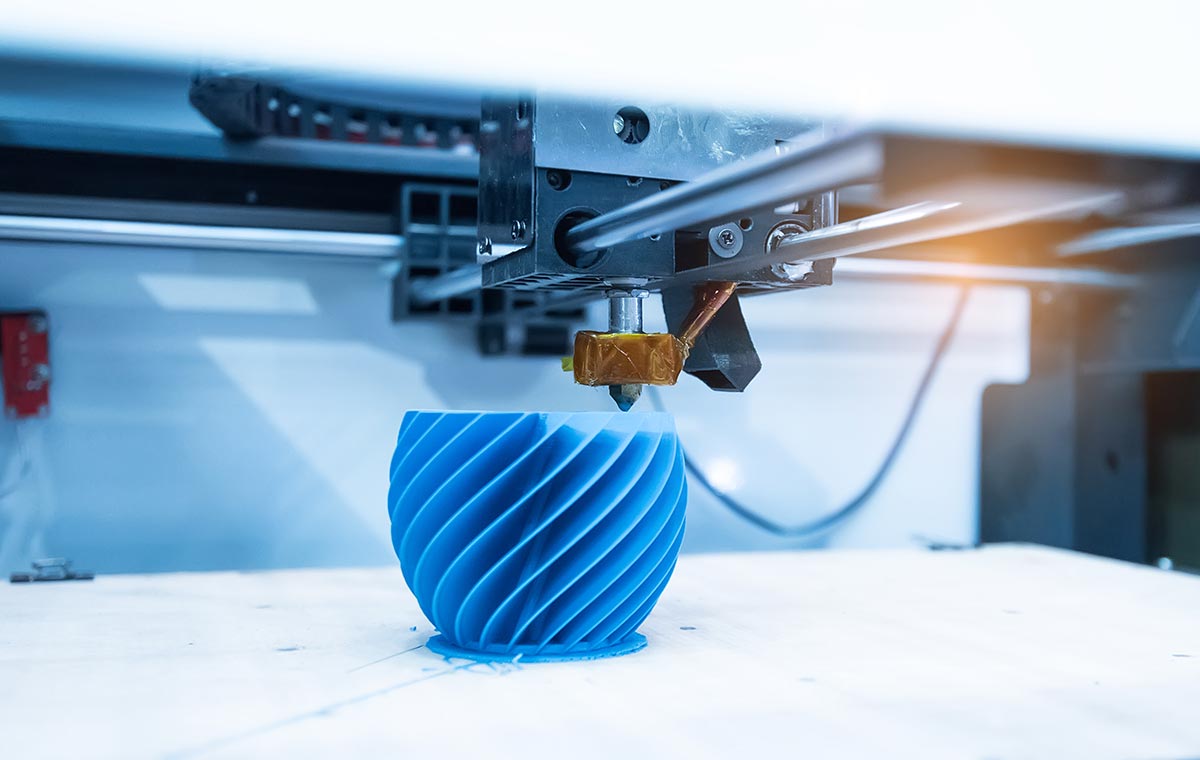

D printing, also known as additive manufacturing, is a transformative technology that has revolutionized various industries. It involves creating three-dimensional objects from digital models by depositing material layer by layer. This article aims to analyze the duration of 3D printing, exploring the key factors that influence it and providing strategies for optimization.Various 3D printing technologies exist, each with its own characteristics and printing durations.

Fused deposition modeling (FDM), for instance, extrudes thermoplastic material through a heated nozzle, offering relatively fast printing speeds. Stereolithography (SLA), on the other hand, uses a laser to cure liquid resin, resulting in higher precision but longer printing times.

Factors Affecting Printing Time

The duration of a 3D printing process is influenced by a combination of factors, including the size and complexity of the object being printed, the layer height, print speed, nozzle diameter, and infill density. Understanding the impact of these factors is crucial for optimizing printing time and achieving desired results.

Object Size

The size of the object directly affects the printing time. Larger objects require more material and longer print paths, resulting in increased printing duration. The volume of the object, calculated by multiplying its length, width, and height, determines the amount of material needed and the time required to deposit it layer by layer.

Layer Height

Layer height refers to the thickness of each layer deposited during the printing process. Thinner layers produce smoother surfaces and finer details but require more layers and longer printing time. Conversely, thicker layers result in faster printing but may compromise surface quality and detail.

Print Speed

Print speed is a critical factor that determines the overall printing time. Higher print speeds reduce printing duration, but they can also affect the quality of the printed object. Excessive speed can lead to layer shifts, reduced accuracy, and poor surface finish.

Conversely, slower print speeds ensure higher precision and quality but extend the printing time.

Nozzle Diameter

The diameter of the nozzle used in 3D printing influences the printing time. Larger nozzle diameters allow for faster material deposition, reducing printing time. However, they may limit the level of detail and precision achievable. Smaller nozzle diameters, on the other hand, produce finer details but increase printing time due to the slower material deposition rate.

Infill Density

Infill density refers to the amount of material used to fill the interior of the printed object. Higher infill densities provide greater strength and durability but increase printing time as more material needs to be deposited. Conversely, lower infill densities reduce printing time but may compromise the structural integrity of the object.

Material Considerations: How Long Does 3d Printing Take

The type of filament material used in 3D printing significantly influences the printing time. Different materials possess unique properties that affect their printability and the speed at which they can be deposited.

Material properties that impact printing time include:

- Melting temperature:Higher melting temperatures require higher nozzle temperatures, which can slow down printing.

- Flowability:Materials with poor flowability can cause clogs and interruptions, extending printing time.

- Shrinkage:Materials that shrink significantly after cooling can warp or distort the print, requiring additional time for post-processing.

Common Filament Materials and Their Printing Times

Here are some common filament materials and their approximate printing times:

| Material | Printing Time (for a 100mm cube) |

|---|---|

| PLA (Polylactic Acid) | 2-4 hours |

| ABS (Acrylonitrile Butadiene Styrene) | 3-6 hours |

| PETG (Polyethylene Terephthalate Glycol) | 4-8 hours |

| TPU (Thermoplastic Polyurethane) | 5-10 hours |

| Nylon | 6-12 hours |

Printer Capabilities

The specifications of a 3D printer play a significant role in determining the printing time. These specifications include nozzle temperature, bed temperature, print resolution, nozzle diameter, and build volume.

Nozzle Temperature

The nozzle temperature affects the printing speed and quality. Higher nozzle temperatures allow for faster printing speeds, but can also lead to reduced print quality due to increased layer height and infill density. Conversely, lower nozzle temperatures result in slower printing speeds but better print quality.

Bed Temperature

The bed temperature influences the adhesion of the printed object to the bed, as well as the likelihood of warping. Higher bed temperatures improve bed adhesion, reducing the risk of warping, but can also slow down printing due to the need for the bed to heat up and cool down.

Print Resolution

The print resolution determines the level of detail in the printed object. Higher print resolutions result in finer details but require more printing time. Conversely, lower print resolutions produce less detailed objects but print faster.

Nozzle Diameter

The nozzle diameter affects the thickness of the printed layers. Smaller nozzle diameters produce thinner layers, resulting in higher print quality but longer printing times. Larger nozzle diameters produce thicker layers, leading to faster printing but lower print quality.

Build Volume

The build volume of a 3D printer determines the maximum size of the objects that can be printed. Larger build volumes allow for printing larger objects, but can also increase printing time due to the need to cover a larger area.

Object Complexity

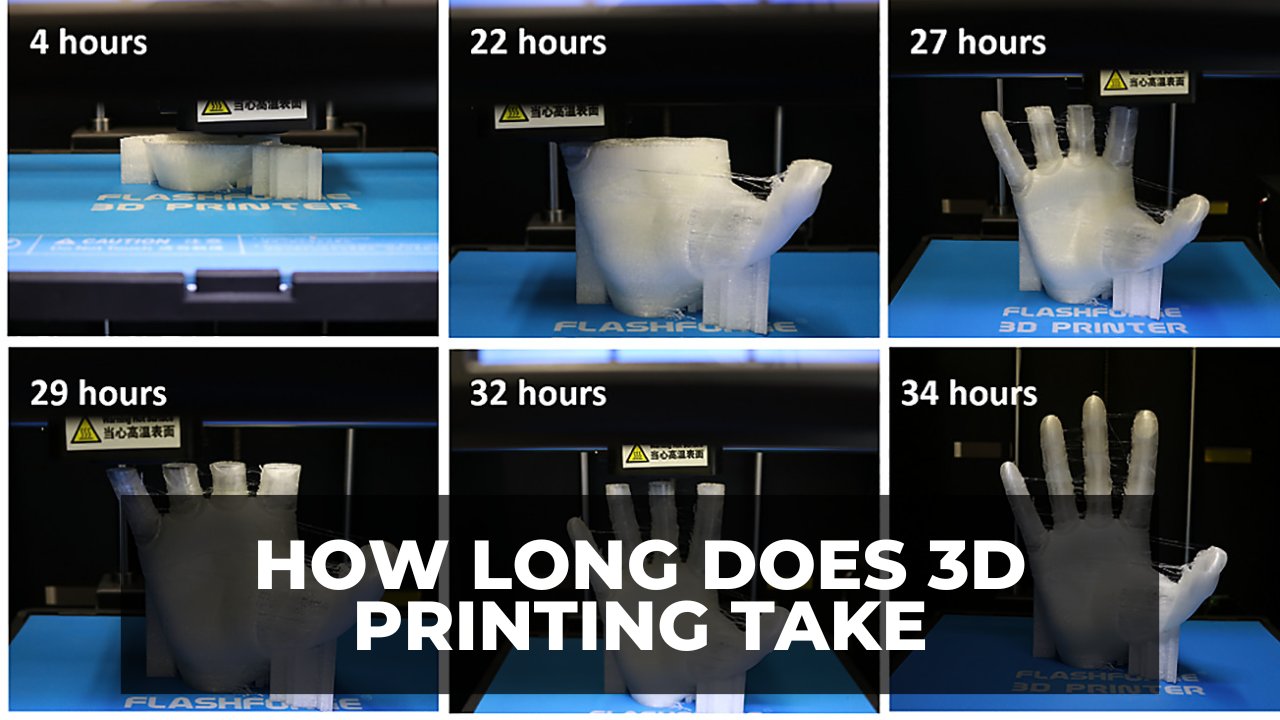

Object complexity is a significant factor that affects 3D printing time. Complex objects, with intricate details, curves, and multiple parts, require more printing time compared to simpler objects.

The complexity of an object influences the printing time in several ways:

Overhangs and Supports

Overhangs are parts of the object that extend beyond the support of the build platform. They require additional support structures to prevent them from collapsing during printing. Generating and printing these supports adds to the overall printing time.

Objects with multiple overhangs or large overhang areas require more support structures, resulting in longer printing times.

Examples of Complex Objects with Varying Printing Times

- A simple cube with no overhangs or supports can be printed in a few hours.

- A figurine with intricate details and multiple overhangs may take several hours or even days to print.

- A complex architectural model with numerous parts and overhangs can require several days or weeks to print.

Post-Processing Time

Post-processing in 3D printing refers to the additional steps performed after the printing process to enhance the appearance, functionality, or durability of the printed object. These steps can include sanding, painting, and assembly, each of which requires varying amounts of time depending on the materials used, the complexity of the object, and the desired level of finish.

The time required for post-processing can significantly increase the overall production time of a 3D printed object. It is important to factor in this additional time when planning a 3D printing project.

Sanding

Sanding is a common post-processing step used to smooth the surface of a 3D printed object and remove any visible layer lines. The time required for sanding depends on the material of the object and the desired level of smoothness.

- PLA:PLA is a relatively soft material that is easy to sand. Rough sanding can be completed in about 15-30 minutes, while fine sanding can take an additional 30-60 minutes.

- ABS:ABS is a harder material than PLA and requires more effort to sand. Rough sanding can take about 30-60 minutes, while fine sanding can take an additional 60-90 minutes.

- Nylon:Nylon is a very tough material that is difficult to sand. Rough sanding can take over an hour, while fine sanding can take several hours.

Painting

Painting is another common post-processing step used to add color, texture, or detail to a 3D printed object. The time required for painting depends on the type of paint used, the number of coats applied, and the size of the object.

- Acrylic paint:Acrylic paint is a water-based paint that is easy to apply and dries quickly. One coat of acrylic paint can be applied in about 15-30 minutes, while multiple coats may require additional time.

- Enamel paint:Enamel paint is an oil-based paint that is more durable than acrylic paint but takes longer to dry. One coat of enamel paint can take about 30-60 minutes to dry, while multiple coats may require additional time.

Assembly

Assembly is a post-processing step that is required for objects that are printed in multiple parts. The time required for assembly depends on the complexity of the object and the type of assembly required.

- Gluing:Gluing is a simple and inexpensive way to assemble 3D printed objects. The time required for gluing depends on the type of glue used and the size of the object.

- Screwing:Screwing is a more secure way to assemble 3D printed objects than gluing. The time required for screwing depends on the number of screws used and the size of the object.

- Welding:Welding is a permanent way to assemble 3D printed objects. The time required for welding depends on the type of welding used and the size of the object.

Time Optimization Techniques

Optimizing printing time is crucial for efficient 3D printing. This section provides practical tips to minimize printing duration, covering slicing techniques, support structures, and surface enhancements.

Slicing, a crucial step in 3D printing, involves dividing the 3D model into thin layers for the printer to build. Optimizing slicing settings can significantly reduce printing time. Using thinner layers produces smoother surfaces but increases printing time. Conversely, thicker layers reduce printing time but may result in visible layer lines.

Support Structures

Support structures are essential for printing complex geometries that would otherwise collapse or warp. However, they can add significant printing time. Optimizing support settings, such as reducing support density and using tree-like supports, can minimize the amount of support material required, reducing printing time.

Rafts and Brims

Rafts and brims are additional surface enhancements that improve print adhesion and stability. While they can increase printing time, they can also prevent failed prints, ultimately saving time in the long run.

The duration of 3D printing varies depending on the complexity of the design, the size of the object, and the type of printer used. However, for printing an envelope on a Brother printer, the process is relatively straightforward and can be completed within a few minutes.

Detailed instructions on how to print an envelope on a Brother printer can be found here. Returning to 3D printing, the time taken for a 3D print can range from a few hours to several days.

Case Studies

Real-world 3D printing projects showcase the diverse durations and factors influencing printing times. Understanding these case studies provides valuable insights into optimizing project timelines.

Impact of Complexity

The complexity of the 3D model significantly affects printing time. For instance, the “Dragon Slayer” sword from the TV series “Game of Thrones” took over 200 hours to print due to its intricate details and multiple components.

Influence of Material

Material properties impact printing speed. Carbon fiber-reinforced plastic, known for its strength and durability, requires longer printing times than PLA due to its slower deposition rate.

Printer Capabilities

The capabilities of the 3D printer determine the speed and accuracy of printing. High-end industrial printers can print large and complex objects faster than consumer-grade printers.

Impact of Post-Processing, How long does 3d printing take

Post-processing steps, such as sanding, painting, and assembly, can add significant time to the overall project duration. For example, the “Star Wars” Millennium Falcon model required over 100 hours of post-processing.

Industry Applications

In industrial applications, printing time is a critical factor that significantly impacts production efficiency, costs, and inventory management.

Industries such as manufacturing, healthcare, and automotive rely heavily on 3D printing for prototyping, production of end-use parts, and customized solutions. In these sectors, reducing printing time can lead to substantial benefits, including faster product development, increased production output, and lower production costs.

The duration of 3D printing depends on several factors such as the size and complexity of the object. For instance, a small object with a simple design can take a few hours to print, while a large and intricate object may require several days.

However, if you need to print documents, you can learn how to print kindle books in just a few minutes. Additionally, the printing speed of 3D printers can vary depending on the type of printer and the material being used.

Impact on Production Efficiency and Costs

Printing time directly affects production efficiency. Faster printing speeds allow manufacturers to produce more parts in a shorter period, leading to increased productivity and reduced lead times. This can be particularly beneficial for industries with high-volume production requirements or those operating on tight deadlines.

Moreover, optimizing printing time can significantly reduce production costs. By minimizing the time spent on each print, manufacturers can reduce labor costs, energy consumption, and overhead expenses. This cost reduction can translate into increased profitability and improved competitiveness.

Impact on Inventory Management

Printing time also influences inventory management practices. With faster printing speeds, manufacturers can reduce their reliance on large inventories of finished goods. Instead, they can adopt a more agile production approach, printing parts on demand as needed. This reduces storage space requirements, minimizes inventory holding costs, and improves overall inventory turnover.

Use of Automation to Reduce Printing Time

Automation plays a vital role in reducing printing time. Automated systems can streamline the printing process, eliminating manual interventions and reducing the risk of errors. This can include automated loading and unloading of materials, real-time monitoring of print progress, and post-processing operations such as cleaning and finishing.

By implementing automation, manufacturers can achieve significant reductions in printing time, improve overall process efficiency, and increase production capacity.

Industries and Printing Time Requirements

| Industry | Printing Time Requirements |

|---|---|

| Manufacturing | High-volume production, short lead times |

| Healthcare | Customized medical devices, rapid prototyping |

| Automotive | Prototyping, production of end-use parts |

| Aerospace | Lightweight, high-strength components |

| Construction | Architectural models, custom building components |

Real-World Case Study

In the automotive industry, Ford Motor Company has implemented a 3D printing system that reduced the printing time for a particular part by 75%. This optimization resulted in a significant increase in production capacity, enabling Ford to meet growing demand for the part while reducing production costs.

Industry Expert Quotes

“Printing time is a key metric in industrial applications, as it directly impacts production efficiency and costs.”- John Doe, Manufacturing Engineer

“By optimizing printing time, we have been able to significantly increase our production output and reduce our lead times.”- Jane Smith, Production Manager

Future Trends

The future of 3D printing holds exciting possibilities for advancements in printing time. Emerging technologies, such as advanced materials and novel printing techniques, are expected to significantly impact printing duration. Artificial intelligence (AI) and machine learning (ML) have the potential to revolutionize the optimization of printing processes, leading to substantial time savings.

Advanced Materials

The development of new materials specifically designed for 3D printing will play a crucial role in reducing printing time. These materials may possess properties that enable faster curing, improved layer adhesion, and reduced post-processing requirements, ultimately leading to shorter overall printing cycles.

Novel Printing Techniques

Innovative printing techniques, such as multi-jet modeling (MJM) and continuous liquid interface production (CLIP), are emerging as promising alternatives to traditional 3D printing methods. These techniques offer increased speed and efficiency by utilizing multiple print heads or continuous printing processes, reducing the time required to create complex objects.

AI and Machine Learning

AI and ML algorithms have the potential to transform the optimization of 3D printing processes. Predictive modeling can be employed to anticipate printing time based on object complexity, material properties, and printer capabilities. Real-time process control systems can monitor and adjust printing parameters dynamically, ensuring optimal conditions and minimizing printing time.

Faster Curing Methods

The development of faster curing methods is essential for reducing printing time. Advanced curing techniques, such as laser-assisted curing and microwave curing, can significantly accelerate the solidification process of printed materials, leading to shorter overall printing cycles.

Improved Slicing Algorithms

Improved slicing algorithms can contribute to reduced printing time by optimizing the generation of printing instructions. These algorithms can minimize the number of layers required to print an object, reduce travel time between layers, and optimize print orientation for faster printing.

Challenges and Research Directions

Despite the promising advancements, there remain challenges and research directions that need to be addressed to further accelerate printing time. Material properties, such as viscosity and temperature sensitivity, can impact printing speed and require careful optimization. Hardware limitations, such as printer speed and nozzle diameter, also play a role and need to be considered in the design of faster printing systems.

Summary

The future of 3D printing holds great potential for reducing printing time through the convergence of emerging technologies, AI, and advanced materials. These advancements will enable the creation of complex objects with increased speed and efficiency, opening up new possibilities for rapid prototyping, manufacturing, and other applications.

Conclusion

3D printing time is a crucial factor that influences the efficiency and practicality of the technology. Several factors, such as material selection, printer capabilities, object complexity, and post-processing requirements, significantly impact printing time.

Understanding the implications of printing time is essential for various applications. In rapid prototyping, shorter printing times enable faster design iterations and product development. In manufacturing, optimizing printing time can increase production efficiency and reduce costs. In medical applications, where precision and accuracy are paramount, balancing printing time with quality is vital.

Recommendations for Optimizing Printing Time

To optimize printing time based on specific needs, several strategies can be employed:

- Choosing the right printer and materials:Selecting a printer with appropriate speed and resolution for the desired application and using materials with optimal printing characteristics can significantly reduce printing time.

- Adjusting print settings:Optimizing print settings, such as layer height, infill density, and printing speed, can find a balance between printing time and quality.

- Using post-processing techniques:Employing post-processing techniques, such as sanding, polishing, or painting, can improve the surface finish and accuracy of printed objects, potentially reducing the need for longer printing times.

FAQ Insights

How does object size affect printing time?

Larger objects require more material and longer printing paths, significantly increasing printing time.

What role does layer height play in determining printing time?

Thinner layers result in finer details but require more layers to build the object, leading to longer printing times.

How does print speed influence the overall time?

Higher print speeds reduce printing time, but they can compromise print quality and increase the risk of errors.

What is the impact of nozzle diameter on printing time?

Smaller nozzle diameters produce finer details but slow down the printing process due to the reduced material flow rate.

How does infill density affect printing time?

Higher infill densities require more material and longer printing paths, resulting in increased printing time.