Can I print on cardstock? The answer is a resounding yes! Dive into this comprehensive guide to explore the possibilities and techniques of printing on cardstock, unlocking a world of creative and professional applications.

Whether you’re a seasoned printer or just starting out, this guide will provide you with the knowledge and tips you need to achieve stunning results on cardstock. From choosing the right printer and cardstock to troubleshooting common issues, we’ve got you covered.

Printers Compatible with Cardstock

Various types of printers are compatible with cardstock, including:

Inkjet Printers

- Inkjet printers use liquid ink that is sprayed onto the paper. They are generally more affordable than laser printers and can produce high-quality prints on cardstock.

- However, inkjet printers may require special cardstock that is designed to absorb ink without smudging.

Laser Printers

- Laser printers use a laser to create an electrostatic image on the paper, which is then fused with toner powder. They are generally faster and more efficient than inkjet printers and can produce sharp, professional-looking prints on cardstock.

- Laser printers typically do not require special cardstock, but it is important to use a cardstock that is compatible with the printer’s fuser temperature.

Differences Between Inkjet and Laser Printers for Cardstock Printing, Can i print on cardstock

- Inkjet printers are generally more affordable and can produce high-quality prints on cardstock, but may require special cardstock.

- Laser printers are generally faster and more efficient and can produce sharp, professional-looking prints on cardstock, but may not require special cardstock.

Advantages and Disadvantages of Using Cardstock with Different Types of Printers

| Printer Type | Advantages | Disadvantages |

|---|---|---|

| Inkjet | – More affordable

| – May require special cardstock

|

| Laser | – Faster print speeds

| – May not require special cardstock

|

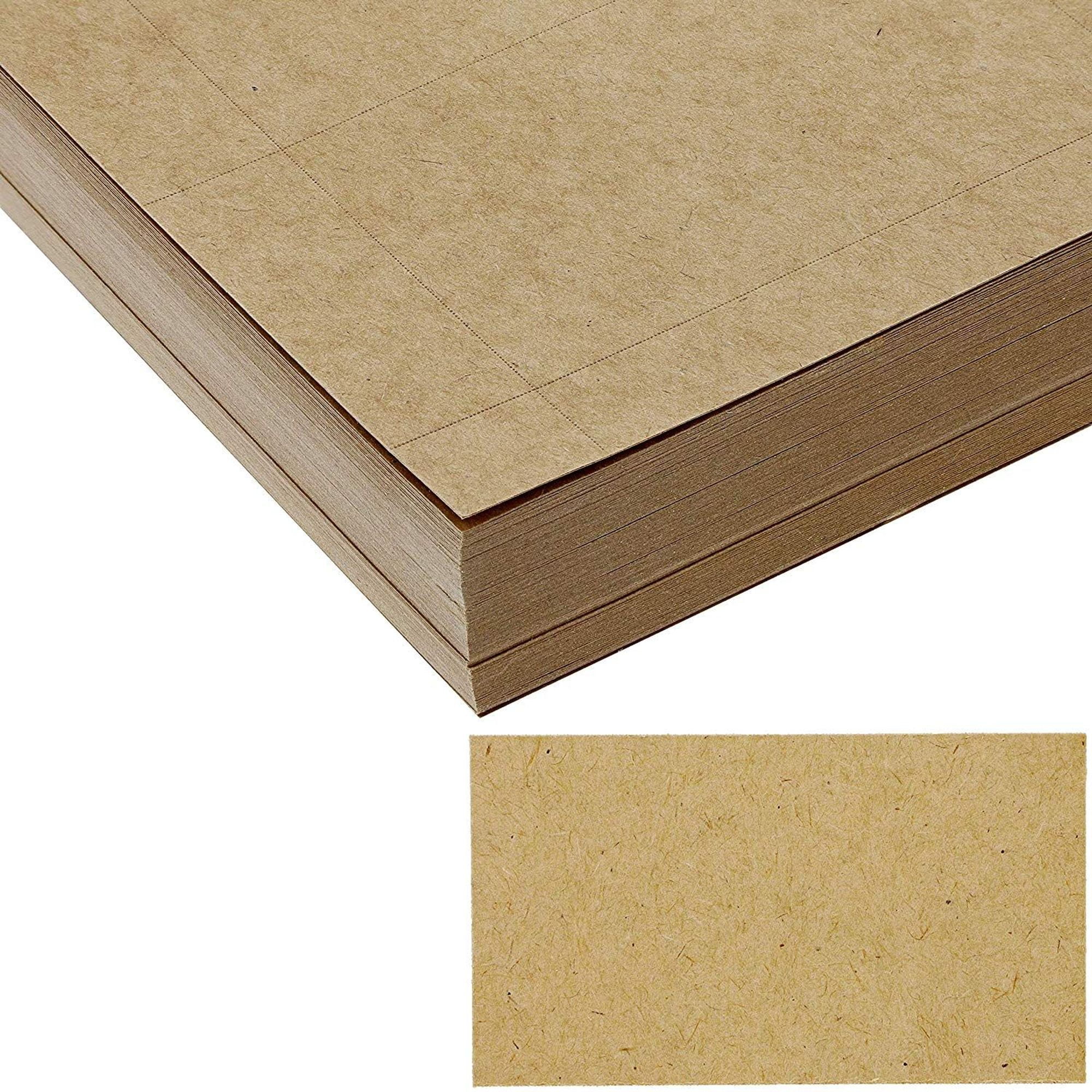

Cardstock Types and Their Suitability

Cardstock, a thicker and more durable paper, is available in various types, each with unique characteristics that impact printability and the final results. Understanding these variations is crucial for selecting the appropriate cardstock for different printing applications.

Weight

Cardstock weight, measured in pounds per ream (lb/ream) or grams per square meter (gsm), significantly influences its thickness and stiffness. Heavier cardstock (e.g., 110 lb/ream or 300 gsm) provides a more substantial feel and is suitable for applications like business cards, covers, and postcards.

Lighter cardstock (e.g., 65 lb/ream or 176 gsm) is thinner and more flexible, making it ideal for flyers, brochures, and invitations.

Texture

Cardstock texture refers to the surface finish, which can range from smooth to textured. Smooth cardstock (e.g., satin or matte) provides a professional and polished look, while textured cardstock (e.g., linen or felt) adds a tactile element and can enhance the visual appeal.

The texture can also affect ink absorption and printability.

Color

Cardstock is available in a wide range of colors, from classic white and black to vibrant hues. Color choice depends on the desired aesthetic and can complement or contrast the printed design. Colored cardstock can enhance the visual impact and create a memorable impression.

Table: Cardstock Types and Uses

The following table summarizes the characteristics and uses of different cardstock types:

| Type | Weight | Texture | Uses |

|---|---|---|---|

| Standard | 65-110 lb/ream | Smooth or textured | Flyers, brochures, invitations, business cards |

| Premium | 120-160 lb/ream | Smooth or textured | Business cards, covers, postcards, invitations |

| Ultra-Premium | 170 lb/ream or higher | Smooth or textured | Business cards, covers, luxury invitations |

| Colored | 65-110 lb/ream | Smooth or textured | Flyers, brochures, invitations, business cards |

| Metallic | 65-110 lb/ream | Smooth or textured | Business cards, invitations, covers |

Specific Examples

For business cards, premium cardstock (120-160 lb/ream) with a smooth texture is recommended to convey professionalism and durability. Flyers and brochures often use standard cardstock (65-110 lb/ream) with a smooth or textured finish, depending on the desired aesthetic. Ultra-premium cardstock (170 lb/ream or higher) with a smooth texture is ideal for luxury invitations or covers, as it provides a substantial feel and a polished appearance.

Printer Settings for Cardstock

To ensure optimal results when printing on cardstock, specific printer settings should be adjusted. These settings include paper size, paper type, and print quality.

Paper Size

The paper size setting must match the dimensions of the cardstock being used. Selecting the correct paper size prevents the printer from attempting to adjust the document to an inappropriate size, which can result in misalignment or other printing issues.

When printing on cardstock, it’s essential to consider the capabilities of your printer. Some printers are designed to handle thicker paper types like cardstock, while others may struggle. If you’re unsure about your printer’s capabilities, refer to the manufacturer’s specifications.

Duplex printers, which can print on both sides of a page automatically, offer convenience and efficiency. Understanding the features of duplex printers can help you determine if they are a suitable choice for your cardstock printing needs.

Paper Type

The paper type setting should be set to “Cardstock” or a similar option. This setting informs the printer that it is printing on a thicker and more rigid material, allowing it to adjust the print head and other components accordingly.

Print Quality

For the best results, the print quality setting should be set to “High” or “Best.” This setting ensures that the printer uses the highest resolution and finest detail, resulting in crisp and vibrant prints on cardstock.

Common Printing Issues with Cardstock

Printing on cardstock can be challenging due to its thickness and rigidity. Several common issues can arise, including smudging, jamming, and poor print quality. Understanding these problems and their solutions can help ensure successful printing on cardstock.

Smudging

- Cause:Ink not drying quickly enough on the cardstock’s surface.

- Solution:Use fast-drying inks, adjust printer settings for slower printing, or allow prints to dry thoroughly before handling.

Jamming

- Cause:Cardstock too thick for the printer’s paper path or not properly aligned.

- Solution:Ensure the cardstock thickness is compatible with the printer, adjust paper guides correctly, and clean the printer’s rollers regularly.

Poor Print Quality

- Cause:Ink not adhering properly to the cardstock’s surface or printer settings not optimized for cardstock.

- Solution:Use inks specifically designed for cardstock, adjust printer settings for higher print quality, and ensure the printer is well-maintained.

Loading Cardstock into the Printer: Can I Print On Cardstock

Loading cardstock into a printer is a crucial step to ensure successful printing on this thicker and stiffer paper type. Different types of printers may have varying loading mechanisms, so it’s essential to follow the specific instructions for your printer model.

In general, the process of loading cardstock involves inserting the paper into a designated tray or feeder, ensuring it is properly aligned and securely held. It’s important to note that cardstock is typically thicker than regular paper, so it may require adjusting the paper guides or settings within the printer to accommodate its thickness.

Loading Cardstock into Tray Feeders

Many printers feature tray feeders that allow for loading cardstock directly into the machine. To load cardstock into a tray feeder:

- Open the printer’s input tray.

- Adjust the paper guides to match the width of the cardstock.

- Insert the cardstock into the tray, ensuring it is flat and aligned.

- Close the input tray.

- Select the “Cardstock” option in the printer’s settings to optimize printing for this paper type.

Loading Cardstock into Rear Feeders

Some printers have rear feeders that provide an alternative method for loading cardstock. To load cardstock into a rear feeder:

- Open the printer’s rear feeder.

- Adjust the paper guides to match the width of the cardstock.

- Insert the cardstock into the feeder, ensuring it is flat and aligned.

- Close the rear feeder.

- Select the “Rear Feed” option in the printer’s settings to specify that the cardstock is being loaded from the rear.

Loading Cardstock into Manual Feeders

Manual feeders provide a more direct way to load cardstock into a printer. To load cardstock into a manual feeder:

- Open the printer’s manual feeder.

- Adjust the paper guides to match the width of the cardstock.

- Insert the cardstock into the feeder, ensuring it is flat and aligned.

- Press the “Feed” or “Print” button to initiate printing.

It’s important to note that manual feeders may require additional attention to ensure the cardstock is properly aligned and fed into the printer. If you encounter any issues during the loading process, refer to your printer’s user manual or contact the manufacturer for specific instructions.

Creating High-Quality Prints on Cardstock

Achieving professional-looking prints on cardstock requires careful attention to several factors, including image resolution, color accuracy, and finishing techniques. By selecting the right cardstock and following best practices, you can create stunning prints that meet your desired results.

Selecting the Right Cardstock

The type of cardstock you choose will significantly impact the print quality. Consider the following factors:

- Weight:Cardstock weight is measured in pounds or grams per square meter (gsm). Heavier cardstock is more durable but may require a printer with a higher weight capacity.

- Finish:Cardstock finishes range from matte to glossy. Matte finishes reduce glare, while glossy finishes enhance colors and images.

- Texture:Cardstock can have a smooth or textured surface. Smooth surfaces provide sharp prints, while textured surfaces add a unique touch.

Printer Settings for Cardstock

Adjusting your printer settings is crucial for optimal cardstock printing. Ensure that your printer supports cardstock printing and select the appropriate settings:

- Media Type:Set the media type to “Cardstock” or “Heavyweight Paper.” This adjusts the printer’s pressure and heat settings.

- Print Quality:Choose a high-quality print setting to achieve the best possible resolution.

- Color Management:Enable color management to ensure accurate color reproduction.

Loading Cardstock into the Printer

Handle cardstock carefully to avoid bending or creasing. Follow these steps:

- Check the Input Tray:Ensure the input tray is clear and large enough to accommodate the cardstock.

- Align the Cardstock:Align the cardstock edges with the tray guides.

- Avoid Overloading:Do not overload the input tray to prevent paper jams.

Common Challenges and Solutions

Printing on cardstock can present certain challenges:

- Paper Jams:Ensure the cardstock is properly aligned and the printer is compatible with the cardstock weight.

- Smudging:Use quick-drying inks or let the prints dry completely before handling.

- Color Inaccuracy:Calibrate your printer regularly to ensure accurate color reproduction.

Examples of Successful Cardstock Prints

Well-executed cardstock prints showcase the following characteristics:

- Sharp Images:High-resolution images with clear details.

- Accurate Colors:Vibrant and true-to-life colors.

- Professional Finish:Smooth, crease-free surfaces with a desired texture.

Troubleshooting Print Problems on Cardstock

When printing on cardstock, various issues can arise. Understanding the root causes and implementing appropriate solutions is crucial for successful cardstock printing.

Common problems include streaking, fading, misalignment, and paper jams. Addressing these issues requires a systematic approach, considering factors such as printer settings, cardstock quality, and printer maintenance.

Streaking or Fading

- Insufficient Ink:Ensure the printer has adequate ink levels, especially for dark or vibrant colors.

- Incorrect Print Settings:Verify that the print settings are optimized for cardstock, including proper resolution and color management.

- Clogged Print Head:Clean the print head using the manufacturer’s recommended procedure to remove any ink buildup or debris.

- Low-Quality Cardstock:Some cardstock may not absorb ink well, leading to streaking or fading. Consider using high-quality cardstock designed for printing.

Misalignment

- Incorrect Paper Feed:Ensure the cardstock is properly aligned in the paper tray and that the printer is set to the correct paper size.

- Faulty Printer Components:Worn or damaged rollers or gears can cause misalignment. Contact the printer manufacturer for maintenance or repair.

- Skewed Cardstock:Flatten the cardstock before loading it into the printer to prevent misalignment due to warping or bending.

Paper Jams

- Overloading the Paper Tray:Avoid overloading the paper tray with too much cardstock, as this can cause jams.

- Incorrect Paper Type:Ensure the printer is set to the correct paper type (cardstock) to prevent feeding issues.

- Damaged Cardstock:Inspect the cardstock for any tears or creases that could cause it to jam in the printer.

Special Considerations for Double-Sided Printing on Cardstock

Double-sided printing on cardstock requires careful attention to ensure optimal results. The thicker nature of cardstock poses unique challenges that must be addressed for successful printing on both sides.

Proper alignment is crucial for double-sided printing. Misalignment can lead to uneven printing or the appearance of shadows on one side of the cardstock. To achieve precise alignment, use a printer with a built-in duplexer or manual duplexing feature. The duplexer ensures accurate alignment by flipping the cardstock over and printing on the other side.

Drying time is another important factor to consider. The thicker material of cardstock takes longer to dry than regular paper. Allowing sufficient drying time between printing on both sides prevents smudging or smearing of the ink.

Printer Settings for Double-Sided Printing

When setting up your printer for double-sided printing on cardstock, adjust the following settings:

- Paper Type:Select “Cardstock” or a similar option to optimize the printing process for thicker paper.

- Duplex Mode:Enable the duplex or manual duplexing feature to allow the printer to print on both sides of the cardstock.

- Print Quality:Choose a higher print quality setting to ensure sharp and vibrant prints on cardstock.

Finishing Techniques for Cardstock Prints

Enhance the appearance and durability of your cardstock prints with various finishing techniques. These techniques add a professional touch, protect the print, and create unique effects.

Laminating

Laminating involves covering the print with a thin, transparent plastic film. This provides protection from moisture, scratches, and fading. It also enhances the colors and gives the print a glossy or matte finish.

Scoring

Scoring is the process of creating a crease in the cardstock without cutting through it. This allows for easy folding and prevents cracking along the fold line. Scoring is commonly used for brochures, greeting cards, and invitations.

Die-Cutting

Die-cutting uses a sharp blade to cut intricate shapes into the cardstock. This technique creates custom shapes, cutouts, and embellishments. Die-cutting is ideal for creating unique business cards, invitations, and packaging.

Choosing the Right Technique

The choice of finishing technique depends on the desired outcome and application. Laminating is suitable for protecting and enhancing prints that will be handled frequently. Scoring is ideal for creating clean folds, while die-cutting allows for unique and intricate designs.

Understanding the capabilities of your printer is crucial when working with different materials. For instance, if you’re wondering “can I print on cardstock,” it’s essential to consult your printer’s specifications. To further enhance your printing experience, you may also want to explore how to scan using a Canon printer.

This comprehensive guide ( how do you scan using a Canon printer ) provides step-by-step instructions and troubleshooting tips for seamless scanning. Returning to our initial inquiry, determining whether your printer supports cardstock printing will ensure successful and high-quality results.

Tips for Professional Results

- Use high-quality cardstock and laminating materials.

- Ensure the print is dry before laminating.

- Use a scoring tool specifically designed for cardstock.

- Test the die-cutting blade on scrap paper before using it on the final print.

Troubleshooting Common Issues

- Laminating bubbles:Use a laminator with adjustable temperature and pressure settings.

- Scoring cracks:Ensure the scoring tool is sharp and the cardstock is not too thick.

- Die-cutting misalignment:Check the alignment of the die-cutting machine and the cardstock.

Importance of Quality Materials and Equipment

High-quality materials and equipment are crucial for achieving professional-looking results. Invest in durable cardstock, sharp scoring tools, and a reliable die-cutting machine to ensure optimal performance and long-lasting prints.

Share Your Insights

Have you tried any of these finishing techniques? Share your experiences and insights in the comments below to help others learn and improve their cardstock printing projects.

Applications and Uses of Cardstock Prints

Cardstock prints offer a wide range of applications due to their durability, versatility, and aesthetic appeal. Businesses and individuals alike leverage cardstock’s unique qualities to create impactful and memorable printed materials.

Beyond traditional uses such as business cards and invitations, cardstock prints have found innovative applications in various industries.

Industries and Businesses Using Cardstock Prints

- Marketing and Advertising:Brochures, flyers, posters, promotional materials

- Education:Certificates, diplomas, flashcards, educational posters

- Healthcare:Medical records, patient charts, appointment cards

- Photography:Photo prints, portfolio presentations, greeting cards

- Retail:Product packaging, gift tags, loyalty cards

- Event Planning:Invitations, menus, table numbers

- Non-Profit Organizations:Fundraising materials, donation forms, membership cards

Advantages and Unique Qualities of Cardstock Prints

“Cardstock’s thickness and durability make it ideal for creating professional-looking prints that withstand handling and frequent use.”- Emily Carter, Graphic Designer

“The versatility of cardstock allows for a wide range of creative applications, from intricate die-cuts to vibrant full-color prints.” – Sarah Jones, Marketing Manager

Creative and Innovative Uses of Cardstock Prints

- Origami and Paper Crafts:Complex and decorative origami models, custom-designed paper flowers

- Art Prints:Limited edition prints, canvas-mounted artwork, abstract designs

- Greeting Cards:Personalized and unique cards for special occasions, pop-up designs

- Packaging:Custom-designed boxes, gift wrapping, product labels

- Wall Decor:Framed prints, photo collages, wall art installations

Environmental Considerations and Sustainability Practices

As with any printed material, environmental considerations are important when using cardstock. Opting for sustainably sourced paper, using eco-friendly inks, and recycling used prints can minimize the environmental impact of cardstock prints.

Environmental Considerations for Cardstock

Cardstock production and use have environmental implications that require consideration. Understanding these impacts and exploring sustainable alternatives and recycling options is crucial for responsible cardstock usage.

Raw Material Sourcing and Extraction

Cardstock is primarily made from wood pulp, requiring the harvesting of trees. Deforestation and unsustainable forestry practices can lead to habitat loss, biodiversity reduction, and soil erosion. Sourcing wood from sustainably managed forests and using recycled materials can mitigate these impacts.

Energy Consumption and Greenhouse Gas Emissions

Cardstock production involves energy-intensive processes such as pulping, bleaching, and drying. These processes contribute to greenhouse gas emissions, particularly carbon dioxide. Optimizing energy efficiency and using renewable energy sources can reduce these emissions.

Water Usage and Wastewater Treatment

Cardstock production requires significant amounts of water, mainly for pulping and bleaching. Wastewater from these processes contains pollutants that must be treated before release. Implementing water-efficient technologies and recycling wastewater can minimize water consumption and pollution.

Sustainable Alternatives to Cardstock

- Recycled or Biodegradable Materials:Using recycled paper or biodegradable materials, such as bamboo or hemp, reduces the need for virgin wood pulp and promotes sustainability.

- Digital Alternatives:Replacing printed materials with digital formats, such as e-documents and online presentations, can significantly reduce paper consumption and environmental impact.

Recycling Options for Cardstock

Recycling cardstock helps conserve resources and reduce waste. However, challenges exist in recycling due to its thickness and potential contamination with inks and coatings. Implementing proper collection and processing systems and increasing market demand for recycled cardstock can enhance recycling rates.

Conclusion

The environmental impact of cardstock production and use necessitates responsible practices. Sustainable alternatives, such as recycled materials and digital formats, can reduce the environmental footprint. Additionally, recycling programs and the development of efficient recycling technologies are essential for mitigating the environmental impact of cardstock.

Advanced Techniques for Printing on Cardstock

Printing on cardstock can yield exceptional results with the right techniques. Employing specialized inks, papers, and printing methods can elevate the quality of your prints. Understanding the benefits and drawbacks of different printing methods for cardstock is crucial for selecting the most suitable option for your desired outcomes.

Selecting the appropriate paper is paramount for achieving optimal results. Consider the desired finish, weight, and texture of the cardstock. Preparing the cardstock before printing ensures optimal adhesion and prevents smudging or smearing. This includes ensuring the cardstock is flat and free of dust or debris.

Troubleshooting Tips for Common Issues

- Curling:Use a heavier cardstock or apply a light coating of hairspray to the printed surface.

- Smudging:Allow ample time for the ink to dry before handling the prints.

- Bleeding:Use high-quality inks and papers designed for cardstock printing.

- Fading:Store prints in a cool, dry place away from direct sunlight.

Experimenting with different printing methods can enhance your results. Explore options such as offset printing, digital printing, and letterpress printing. Each method offers unique advantages and drawbacks. Offset printing provides high-quality prints with vibrant colors, while digital printing is more cost-effective for smaller print runs.

Letterpress printing creates a distinctive embossed effect.

Recommended Inks and Papers

- Inks:Pigment-based inks offer excellent durability and resistance to fading.

- Papers:Choose cardstock with a smooth, coated surface for sharp and vibrant prints.

Mastering advanced techniques for printing on cardstock empowers you to create stunning prints with professional-grade quality. By understanding the nuances of different printing methods, inks, and papers, you can achieve exceptional results that meet your specific requirements.

Case Studies of Successful Cardstock Printing Projects

Cardstock printing has enabled a wide range of creative and impactful projects. From eye-catching marketing materials to exquisite artwork, cardstock’s versatility and quality have been showcased in numerous successful endeavors.

One notable example is the creation of custom greeting cards by an independent artist. By utilizing high-quality cardstock, the artist was able to produce vibrant and tactile cards that conveyed the warmth and personal touch of handwritten messages. The thick and durable nature of the cardstock ensured the cards would withstand handling and maintain their pristine appearance over time.

Marketing and Branding

In the realm of marketing and branding, cardstock has played a crucial role in creating memorable and impactful materials. One such project involved the design of business cards for a tech startup. The designers opted for a thick, textured cardstock that conveyed the company’s modern and innovative image.

The raised print and metallic accents added an extra layer of sophistication, making the cards stand out in a sea of ordinary business cards.

Invitations and Announcements

Cardstock has also proven to be an exceptional choice for invitations and announcements. For a wedding invitation suite, a couple chose a delicate lace-embossed cardstock that exuded elegance and charm. The intricate design and soft texture created a tactile experience that invited guests to share in the couple’s special day.

Art and Photography

Beyond its practical applications, cardstock has also found its place in the world of art and photography. A renowned photographer utilized cardstock as the canvas for a series of stunning nature prints. The textured surface of the cardstock added depth and dimension to the images, capturing the essence of the landscapes in a unique and captivating way.

Top FAQs

Can any printer print on cardstock?

No, not all printers are compatible with cardstock. Check your printer’s specifications to ensure it can handle the thickness and weight of cardstock.

What is the best cardstock for printing?

The best cardstock for printing depends on the desired results. Consider factors such as weight, texture, and brightness when choosing cardstock.

How do I prevent smudging when printing on cardstock?

Allow the ink to dry completely before handling prints to prevent smudging. Use high-quality ink and paper, and adjust printer settings for optimal print quality.