What is infill 3D printing? Infill, the internal structure of a 3D printed object, plays a crucial role in determining its strength, weight, and functionality. By optimizing infill patterns and densities, you can unlock the full potential of 3D printing, creating objects that are both robust and lightweight.

From aerospace components to medical implants, infill optimization is revolutionizing the way we design and manufacture objects. Read on to discover the fascinating world of infill 3D printing and its endless possibilities.

Definition of Infill 3D Printing

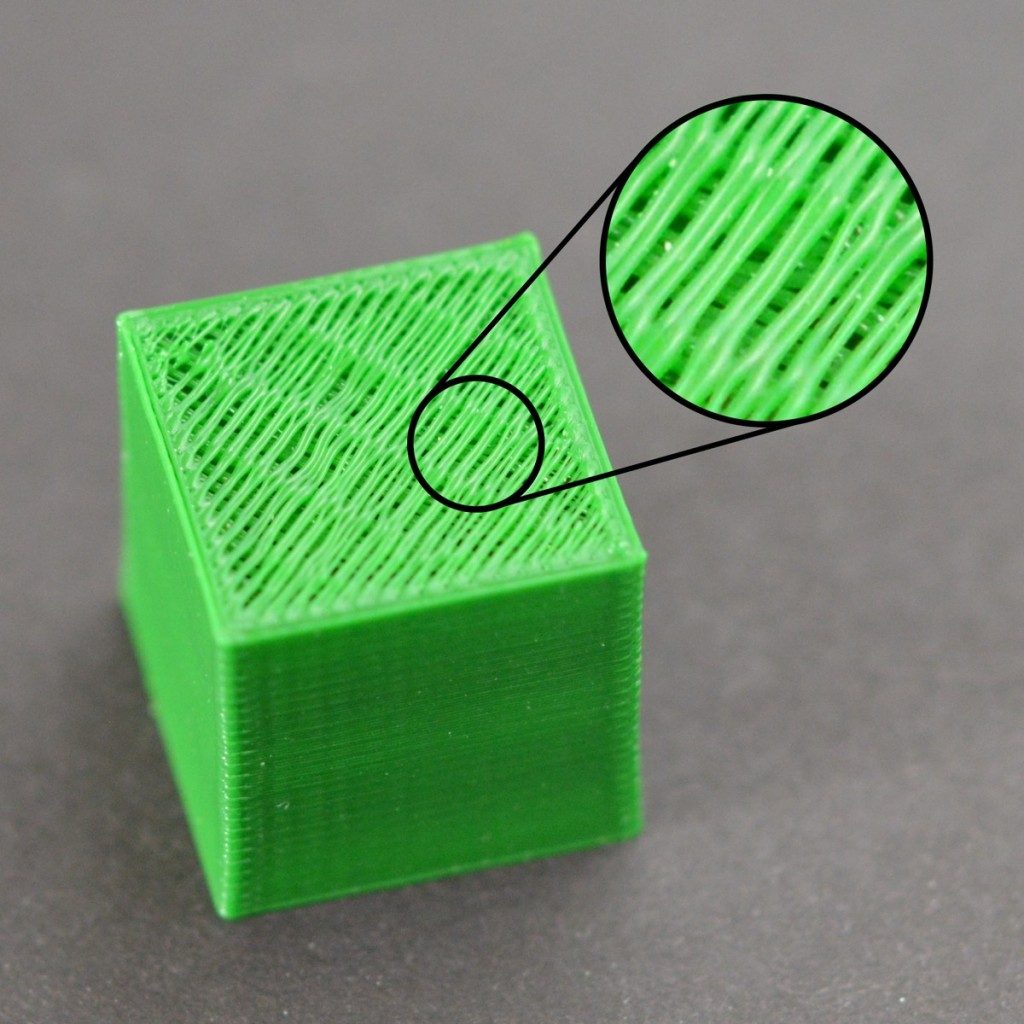

Infill refers to the internal structure of a 3D printed object. It is the material that fills the space between the outer walls of the object. Infill plays a crucial role in determining the strength, durability, and weight of the printed object.

Role of Infill

The density and pattern of infill influence the object’s properties. Higher infill density results in stronger and more durable objects, but it also increases the printing time and material usage. Different infill patterns, such as honeycomb, grid, and triangular, provide varying levels of strength and flexibility.

Factors Influencing Infill Selection

The selection of infill density depends on several factors:

- Print orientation:The orientation of the object during printing affects the distribution of infill and the resulting strength.

- Material properties:The strength and flexibility of the printing material influence the optimal infill density.

- Intended use of the object:The purpose of the printed object determines the required strength and durability, which in turn influences the infill selection.

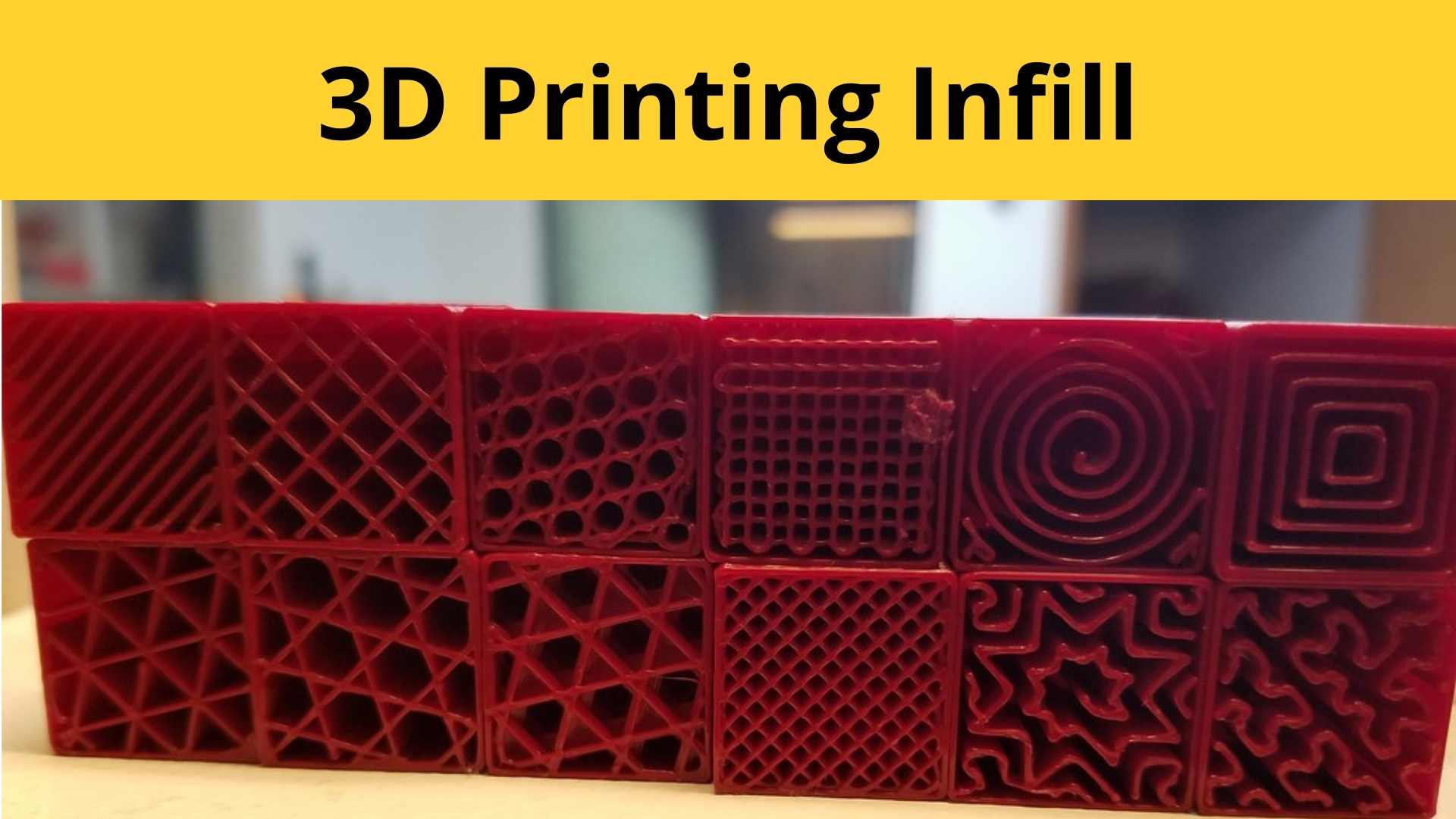

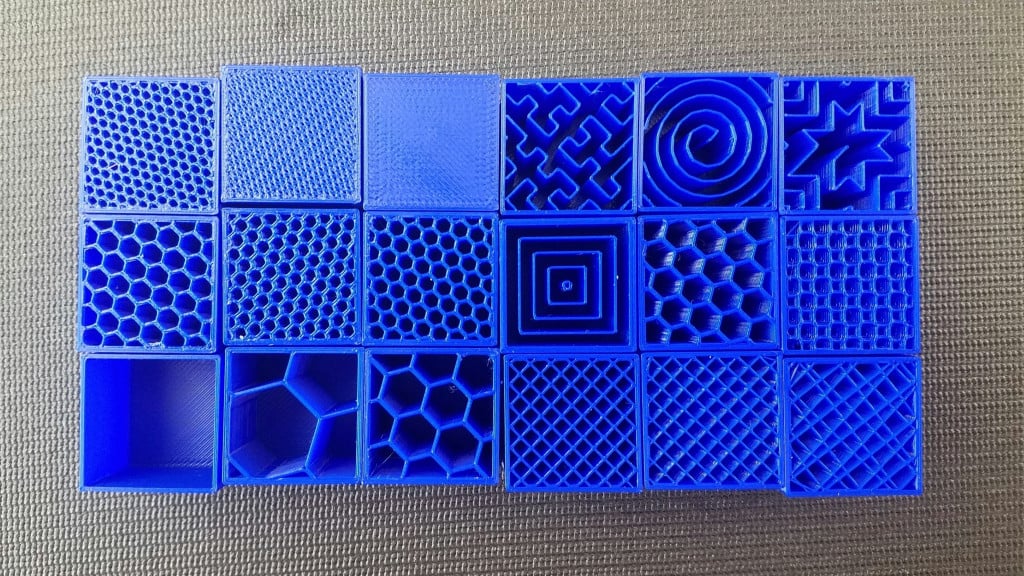

Types of Infill Patterns

Infill patterns refer to the internal structure of a 3D printed object. They significantly influence the object’s strength, weight, and other properties. Different infill patterns offer unique advantages and drawbacks, making the choice of the appropriate pattern crucial.

The selection of an infill pattern depends on several factors, including the material used, the desired properties of the object, and the printing process employed. For instance, objects requiring high strength may benefit from a dense infill pattern, while lightweight objects may utilize a sparse pattern.

Additionally, the printing process can limit the available infill patterns due to factors such as nozzle size and layer height.

Comparison of Infill Patterns

The following table provides a comparison of different infill patterns, highlighting their strengths, weaknesses, and suitable applications:

| Infill Pattern | Strengths | Weaknesses | Applications |

|---|---|---|---|

| Grid | Uniform strength, easy to print | Low strength in specific directions | General-purpose applications, prototypes |

| Honeycomb | High strength-to-weight ratio, energy absorption | Anisotropic strength, more complex to print | Lightweight structures, impact-resistant objects |

| Triangular | Good strength in all directions, low material usage | Slightly weaker than grid, more complex to print | General-purpose applications, functional parts |

| Cubic | Isotropic strength, easy to print | Lower strength-to-weight ratio | Objects requiring strength in multiple directions |

| Concentric | Good layer adhesion, easy to print | Lower strength in the Z-axis | Aesthetic objects, objects with curved surfaces |

| Linear | High strength in one direction, low material usage | Anisotropic strength, not suitable for complex shapes | Structural components, objects with simple geometries |

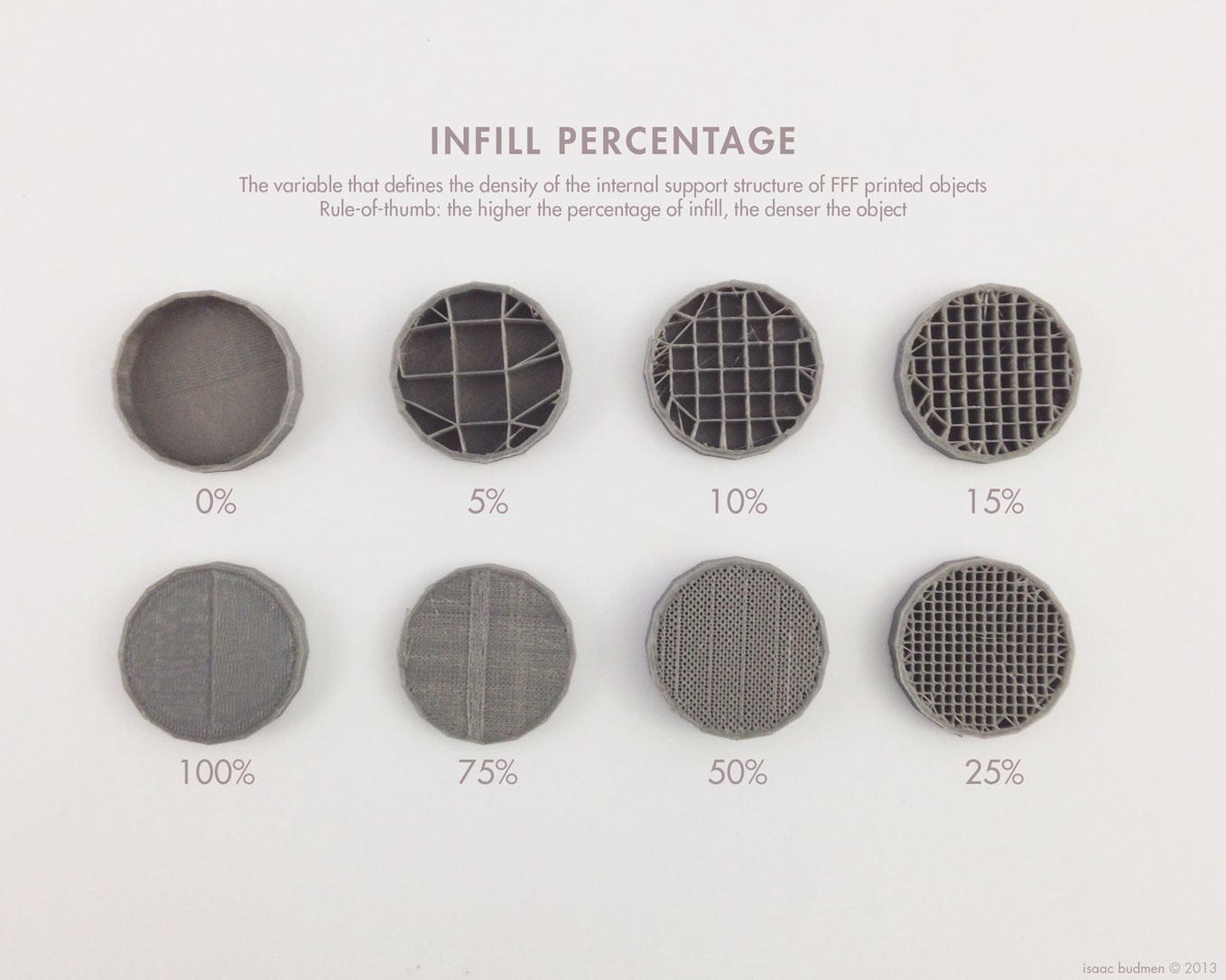

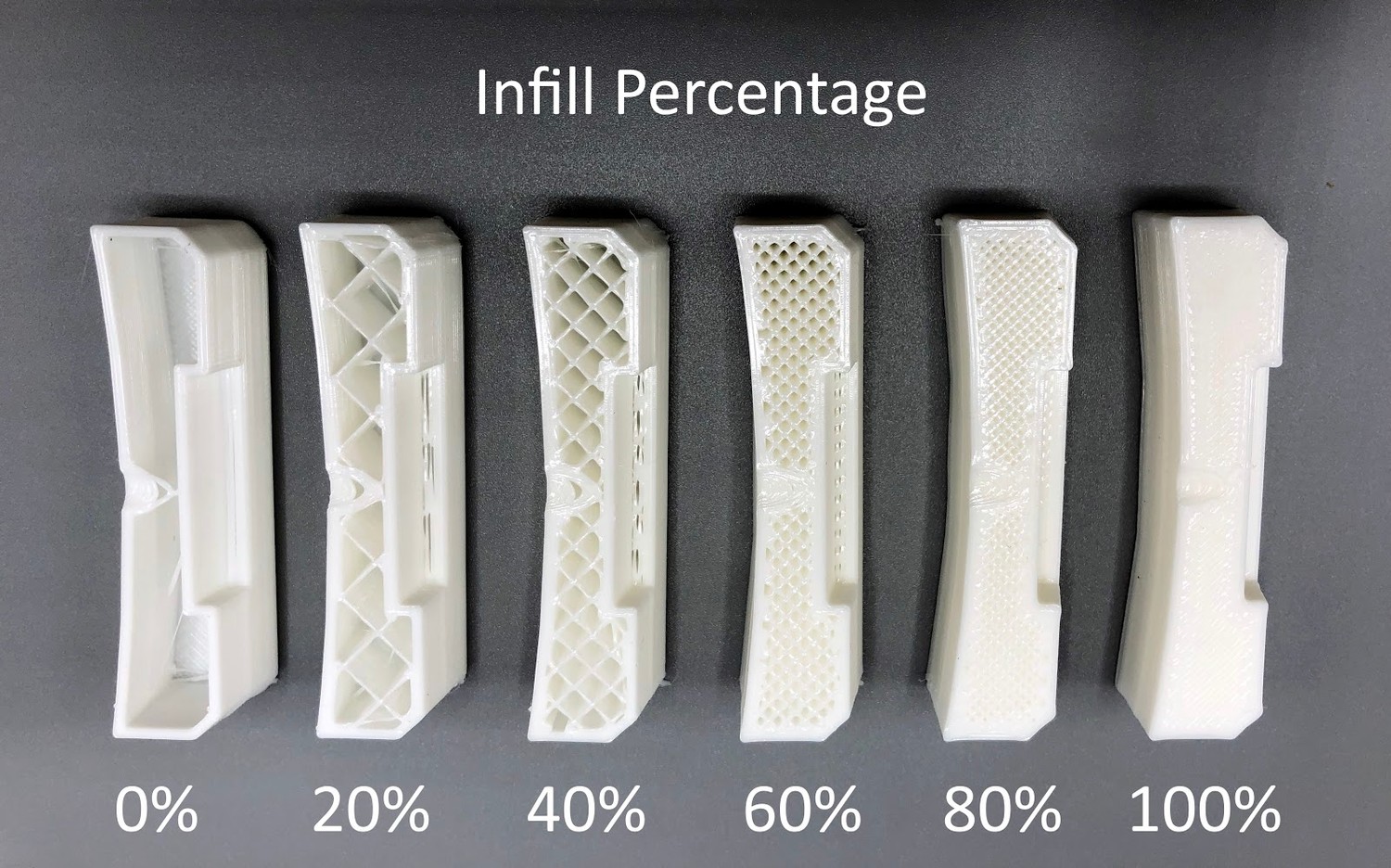

Infill Density and its Impact

Infill density, expressed as a percentage, refers to the amount of material used to fill the interior of a 3D printed object. It significantly influences the object’s weight, strength, and cost.

A higher infill density results in a heavier and stronger object, but also increases printing time and material consumption. Conversely, a lower infill density reduces weight and printing costs, but may compromise strength.

Trade-offs in Choosing Infill Density

The optimal infill density depends on the specific application and requirements.

- Strength:Higher infill densities provide greater structural integrity, making them suitable for load-bearing or functional parts.

- Weight:Lower infill densities reduce weight, making them ideal for applications where weight is a critical factor, such as drones or aerospace components.

- Cost:Higher infill densities require more material and printing time, increasing production costs.

- Printing Time:Objects with higher infill densities take longer to print due to the increased amount of material being deposited.

Infill Density Table

| Infill Density | Weight | Strength | Cost | Recommended Applications ||—|—|—|—|—|| 0-10% | Very Light | Very Weak | Low | Display models, prototypes || 20-30% | Light | Moderate | Moderate | Functional parts, everyday objects || 40-50% | Moderate | Good | High | Structural components, tools || 60-70% | Heavy | Strong | Very High | Load-bearing parts, engineering components || 80-100% | Very Heavy | Very Strong | Extremely High | Critical components, high-strength applications |

Infill 3D printing, a crucial parameter, determines the density and internal structure of a 3D-printed object, influencing its strength, weight, and material consumption. Understanding infill optimization can significantly enhance the efficiency of your printing process. While delving into the intricacies of infill, it’s essential to ensure your printer is operating optimally.

For Epson printer users seeking guidance, refer to the comprehensive guide on how to epson printer reset. By addressing common printer issues, you can maintain optimal performance and ensure high-quality 3D prints with the desired infill settings.

Flowchart for Choosing Infill Density

- Determine the primary function of the object:Is it for structural support, display, or a specific mechanical purpose?

- Consider the weight constraints:Is weight a critical factor, or is strength the priority?

- Evaluate the cost implications:Is the production cost a significant concern?

- Based on these factors, select the appropriate infill density range from the table above.

Sources

Material Considerations for Infill

The choice of infill material significantly impacts the overall performance of the printed object. Different materials possess unique properties and applications, catering to specific design requirements and functional needs.

Material Properties and Applications, What is infill 3d printing

Common infill materials include:

- PLA (Polylactic Acid):Biodegradable, strong, and easy to print. Suitable for general-purpose applications, prototypes, and non-critical parts.

- ABS (Acrylonitrile Butadiene Styrene):Durable, heat-resistant, and impact-resistant. Ideal for functional parts, mechanical components, and objects exposed to harsh environments.

- PETG (Polyethylene Terephthalate Glycol):Strong, flexible, and chemically resistant. Suitable for outdoor applications, containers, and parts requiring flexibility.

- Nylon:Strong, tough, and wear-resistant. Ideal for gears, bearings, and parts subject to high stress or friction.

- TPU (Thermoplastic Polyurethane):Flexible, elastic, and impact-absorbing. Suitable for soft parts, gaskets, and cushioning applications.

Environmental Implications

The environmental impact of infill materials varies depending on their composition and disposal methods.

- PLA:Biodegradable and compostable, reducing environmental footprint.

- ABS:Non-biodegradable and requires proper disposal, posing potential environmental concerns.

- PETG:Recyclable in some areas, reducing waste accumulation.

- Nylon:Non-biodegradable but can be recycled under specific conditions.

- TPU:Non-biodegradable and requires specialized disposal methods.

Material Selection Guidelines

To select the appropriate infill material, consider the following factors:

- Strength and Durability:ABS, Nylon, and PETG provide high strength and durability for demanding applications.

- Flexibility and Impact Resistance:TPU offers exceptional flexibility and impact absorption, making it suitable for soft parts and cushioning applications.

- Biodegradability and Environmental Impact:PLA is the preferred choice for environmentally conscious applications due to its biodegradable nature.

- Cost and Availability:PLA and ABS are widely available and cost-effective, while specialized materials like Nylon and TPU may have higher costs and limited availability.

Design Optimization for Infill

Infill optimization aims to determine the optimal infill pattern and density to achieve specific properties, such as strength, flexibility, or thermal insulation. This optimization process involves understanding the relationship between infill design and the desired properties.

Computer-Aided Design (CAD) Tools

CAD tools provide a platform for designing and optimizing infill patterns. These tools allow engineers to create and simulate different infill patterns, enabling them to analyze the structural integrity, weight, and other properties of the infill. CAD tools can also generate G-code for 3D printing, which is necessary for fabricating the optimized infill design.

Advanced Optimization Techniques

Advanced optimization techniques, such as topology optimization and generative design, can be used to find the optimal infill design for a given set of requirements. Topology optimization involves iteratively removing material from a design space until the desired properties are achieved.

Generative design uses algorithms to explore a wide range of design possibilities and identify the optimal solution.

Infill 3D printing involves filling the interior of a 3D printed object with a material to enhance its strength and durability. This technique is often used in applications where the outer surface of the object is not critical. If you encounter issues with your Brother printer going offline during infill printing, you can refer to troubleshooting guides such as why does my brother printer keep going offline for potential solutions.

Understanding infill 3D printing principles and troubleshooting common issues can help optimize your 3D printing process.

Material Properties and Processing Parameters

The material properties and processing parameters used in 3D printing can significantly impact the performance of infill. The strength, flexibility, and thermal conductivity of the infill material must be considered when selecting an infill pattern. Processing parameters, such as layer height and printing speed, can also affect the quality and properties of the infill.

Examples of Infill Optimization Applications

Infill optimization has been successfully applied in various industries, including aerospace, automotive, and medical. In aerospace, infill optimization has been used to design lightweight and strong aircraft components. In the automotive industry, infill optimization has been used to create lightweight and impact-resistant bumpers.

In the medical industry, infill optimization has been used to design patient-specific implants with tailored properties.

Infill and Support Structures: What Is Infill 3d Printing

In 3D printing, infill plays a crucial role in determining the structural integrity and material usage of a printed part. Infill refers to the internal lattice-like structure that fills the interior of a 3D printed object. It provides support to the outer walls of the print and helps distribute loads evenly throughout the part.

Support structures are temporary structures that are generated during the printing process to provide additional support to overhanging features or complex geometries. They prevent these features from collapsing or warping during printing.

Relationship between Infill and Support Structures

Infill can be used to minimize the need for support structures by providing additional strength and rigidity to the printed part. A higher infill density leads to a stronger part that is less likely to require support. However, it also increases the printing time and material usage.

By carefully selecting the infill pattern and density, it is possible to create parts that have sufficient strength without the need for excessive support structures. This can save time, material, and reduce the post-processing effort required to remove support structures.

Optimizing Infill for Support Reduction

To optimize infill for support reduction, consider the following guidelines:

- Use a high infill density:A higher infill density provides more support and reduces the need for support structures.

- Choose an appropriate infill pattern:Some infill patterns, such as grid or honeycomb, provide better support than others.

- Vary infill density within the part:Increase infill density in areas that require more support, such as overhanging features or areas with high loads.

- Use support blockers:Support blockers are small, temporary structures that can be added to the model to prevent support structures from being generated in specific areas.

By following these guidelines, it is possible to effectively reduce the need for support structures while maintaining the structural integrity of the printed part.

– Infill in FDM and Other 3D Printing Technologies

Infill plays a crucial role in 3D printing technologies beyond FDM (fused deposition modeling). In stereolithography (SLA) and selective laser sintering (SLS), infill determines the internal structure and properties of the printed part.

In SLA, infill is achieved by selectively curing liquid resin with a laser, creating solid regions within the part. SLS uses a laser to fuse powdered material, building up the part layer by layer. Infill in SLS is typically achieved by varying the laser power and scan pattern, creating different densities and porosities within the part.

The choice of infill pattern and density in SLA and SLS depends on factors such as the desired strength, weight, and cost of the part. In general, higher infill densities result in stronger and heavier parts, while lower infill densities produce lighter and less expensive parts.

Infill also plays a role in printing complex geometries, such as overhangs and internal cavities. In FDM, infill can provide support for overhangs, preventing them from collapsing during printing. In SLA and SLS, infill can be used to create internal cavities within the part, which can reduce weight and material usage.

The following table summarizes the key differences between infill in FDM, SLA, and SLS:

| Technology | Infill Method | Strengths | Weaknesses |

|---|---|---|---|

| FDM | Material extrusion | High strength, low cost | Anisotropic properties, visible layer lines |

| SLA | Photopolymerization | High accuracy, smooth surface finish | Limited material selection, post-processing required |

| SLS | Powder bed fusion | Complex geometries, high strength | High cost, limited material selection |

Different Infill Patterns

In addition to the type of 3D printing technology, the choice of infill pattern can also significantly affect the properties of the printed part. Common infill patterns include:

- Honeycomb: A hexagonal pattern that provides good strength and weight reduction.

- Gyroid: A curved pattern that provides excellent strength and impact resistance.

- Cubic: A simple cubic pattern that is easy to print but offers less strength than other patterns.

The choice of infill pattern depends on the desired properties of the part. For example, honeycomb infill is often used for lightweight and strong parts, while gyroid infill is used for parts that require high impact resistance.

Applications of Infill in 3D Printing

Infill plays a crucial role in enhancing the performance and functionality of 3D printed objects. It offers designers and manufacturers the ability to tailor the internal structure of their prints, optimizing them for specific applications and requirements.

The potential of infill extends across various industries, including aerospace, medical, and manufacturing. In aerospace, infill can be used to create lightweight yet strong components for aircraft and spacecraft, reducing fuel consumption and improving overall efficiency. In the medical field, infill can be tailored to create porous structures for bone implants, promoting tissue ingrowth and enhancing patient outcomes.

Infill in Aerospace Applications

- Weight Optimization:By optimizing infill density and pattern, designers can create lightweight structures that meet specific strength requirements, reducing overall weight and improving fuel efficiency.

- Structural Integrity:Infill can be designed to provide structural support and rigidity, ensuring components can withstand the demanding loads and stresses encountered in aerospace applications.

- Thermal Management:Infill can be used to create channels or voids within the structure, facilitating airflow and heat dissipation, which is crucial for electronic components and systems.

Infill in Medical Applications

- Bone Implants:Infill can be tailored to create porous structures that mimic the natural architecture of bone, promoting tissue ingrowth and osseointegration.

- Tissue Engineering:Infill can be used to create scaffolds for growing new tissue, offering a customizable and biocompatible environment for cell proliferation and differentiation.

- Medical Devices:Infill can be optimized to create lightweight and durable medical devices, such as prosthetics and surgical instruments, enhancing patient comfort and functionality.

Future Developments in Infill Technology

The field of infill technology is constantly evolving, with new trends and advancements emerging all the time. One of the most exciting areas of research is the use of artificial intelligence (AI) and machine learning (ML) for infill optimization. These technologies can be used to analyze 3D models and automatically generate infill patterns that are tailored to the specific requirements of each part.

This can lead to significant improvements in part strength, weight, and cost.

Another area of active research is the development of new infill materials and techniques. For example, researchers are exploring the use of lightweight, high-strength materials such as carbon fiber and graphene to create infill patterns that are both strong and lightweight.

Additionally, new techniques such as multi-material printing and 4D printing are being developed to create infill patterns that can change shape or properties over time.

AI and ML for Infill Optimization

AI and ML are powerful tools that can be used to optimize infill patterns for 3D printed parts. These technologies can be used to analyze 3D models and automatically generate infill patterns that are tailored to the specific requirements of each part.

This can lead to significant improvements in part strength, weight, and cost.

One of the most promising applications of AI and ML for infill optimization is the use of generative design. Generative design is a type of AI that can be used to create new designs from scratch. When applied to infill optimization, generative design can be used to create infill patterns that are both strong and lightweight.

This can lead to significant improvements in part performance without increasing the weight or cost of the part.

New Infill Materials and Techniques

The development of new infill materials and techniques is another exciting area of research in the field of infill technology. Researchers are exploring the use of a wide variety of materials to create infill patterns, including lightweight, high-strength materials such as carbon fiber and graphene.

Additionally, new techniques such as multi-material printing and 4D printing are being developed to create infill patterns that can change shape or properties over time.

One of the most promising new infill materials is carbon fiber. Carbon fiber is a lightweight, high-strength material that is often used in aerospace and automotive applications. When used as an infill material, carbon fiber can significantly improve the strength and stiffness of 3D printed parts.

Additionally, carbon fiber is a good thermal conductor, which can help to dissipate heat from 3D printed parts.

FAQ Guide

What is the purpose of infill in 3D printing?

Infill provides structural support, determines strength, and influences the weight and cost of a 3D printed object.

How does infill density affect the strength of a 3D printed object?

Higher infill density results in stronger objects, but it also increases weight and printing time.

What are some common infill patterns?

Honeycomb, gyroid, cubic, and linear are popular infill patterns with varying strengths and applications.